Sintered Metal Filters OEM Service

Lvyuan OEM processes for sintered metal filters involve designing, manufacturing, and supplying filters to be used as components in various industries.

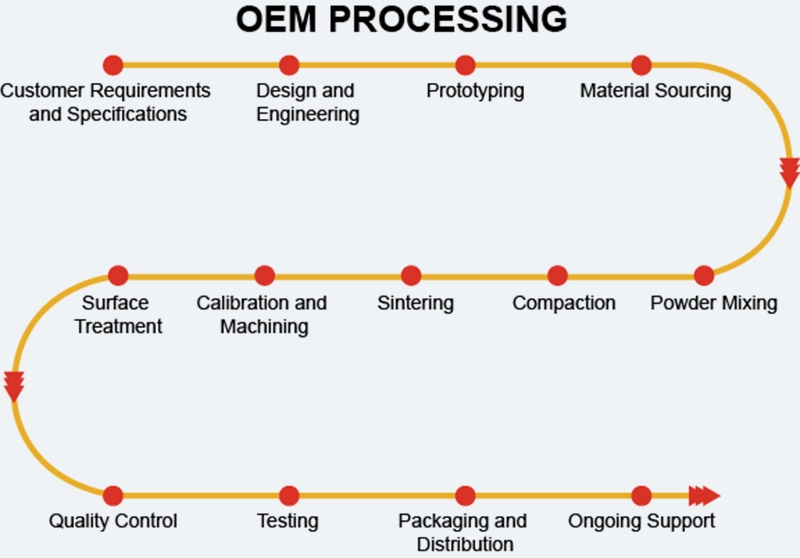

Sintered Metal Filters OEM processing

Below is an outline of the OEM process for sintered metal filters

01

Customer Requirements and Specifications

Understand the specific filtration requirements of the customer. This includes parameters such as particle size, flow rate, temperature, chemical compatibility, and other performance criteria.

02

Design and Engineering

Develop a customized filter design based on the customer's specifications. This involves selecting the appropriate metal alloy, determining the desired pore size distribution, and designing the overall shape and dimensions of the filter.

03

Prototyping

Create a prototype of the sintered metal filter based on the design. Prototyping allows for testing and validation of the filter's performance before mass production.

04

Material Sourcing

Source the required metal powders and other materials needed for the sintering process. Ensure that the materials meet the quality standards and specifications outlined in the design.

05

Powder Mixing

Mix the metal powders according to the specified composition. Additives or binders may also be incorporated to achieve the desired properties in the final sintered metal filter.

06

Compaction

Form the mixed powder into the desired shape using compaction processes. This can involve pressing the powder into molds to create green bodies.

07

Sintering

Subject the green bodies to high temperatures in a controlled atmosphere to sinter the metal particles, creating a solid, porous structure.

08

Calibration and Machining

Calibrate the sintered filters to meet precise dimensional specifications. Machining processes may be employed to achieve specific tolerances or features.

09

Surface Treatment

Apply surface treatments such as coatings or plating to enhance the filter's properties, such as corrosion resistance or chemical compatibility.

10

Quality Control

Implement stringent quality control measures to ensure that each sintered metal filter meets the specified standards. This includes dimensional checks, pore size distribution analysis, and overall structural integrity assessments.

11

Testing

Conduct performance tests on the filters to verify their effectiveness under real-world conditions. This may involve testing with the actual fluids or gases the filters are intended to handle.

12

Packaging and Distribution

Package the filters appropriately for shipment to OEM customers. Ensure proper labeling and documentation accompany the filters.

13

Ongoing Support

Offer ongoing support to OEM customers, including technical assistance, replacement part availability, and collaboration on any design modifications or improvements.

Please contact us

Throughout the OEM process, effective communication between the OEM provider and the customer is essential to ensure that the sintered metal filters meet the intended application requirements.

Additionally, a commitment to quality control and continuous improvement is crucial for delivering reliable and high-performance filters. Tell us your requirements at info@lyfilter.com.

Want to talk to us

Get in touch

Please fill in the form below. We aim to reply within 1 business day.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions