Customized Sintered Metal Filter to Suit Your Requirements

Lvyuan is a professional manufacturer of high-performance sintered metal filters and filter materials for various industries. The company's manufacturing capacity is substantial, with a production workshop covering an area of 1000 square meters. This capacity enables the production of sintered metal fiber felt, multi-layer sintered wire mesh, stainless steel sintered filters, porous metal filters, and special materials such as nickel filters.

The company's products have garnered significant acclaim from its clientele and have emerged as the preferred choice of numerous leading industrial entities across a diverse range of sectors, including petrochemicals, fine chemicals, pulp and paper manufacturing, the automobile industry, food and beverages, and the metal industry. Lvyuan is dedicated to providing professional and independent advice, as well as the most suitable sintered solution for each client, leveraging its independence, experience, and expertise.

A key distinguishing factor of Lvyuan is the superior efficiency of its sintered filters, which surpass the conventional metal woven mesh filters in this regard. These filters are characterized by their exceptional power, durability, and corrosion resistance. Furthermore, the company's dedication to customization enables it to offer filters in different sizes, materials, and layering that will suit the requirements of the customer.

To initiate the process, clients are required to provide information regarding the media type, flow rate, filtration degree, and material. Should a particular brand of sintered metal filter be the object of interest, such as Mott, GKN, or Norman, we request that this is communicated to us. Lvyuan is prepared to furnish a prompt and cost-effective estimate, contingent on the specifications outlined by the client.

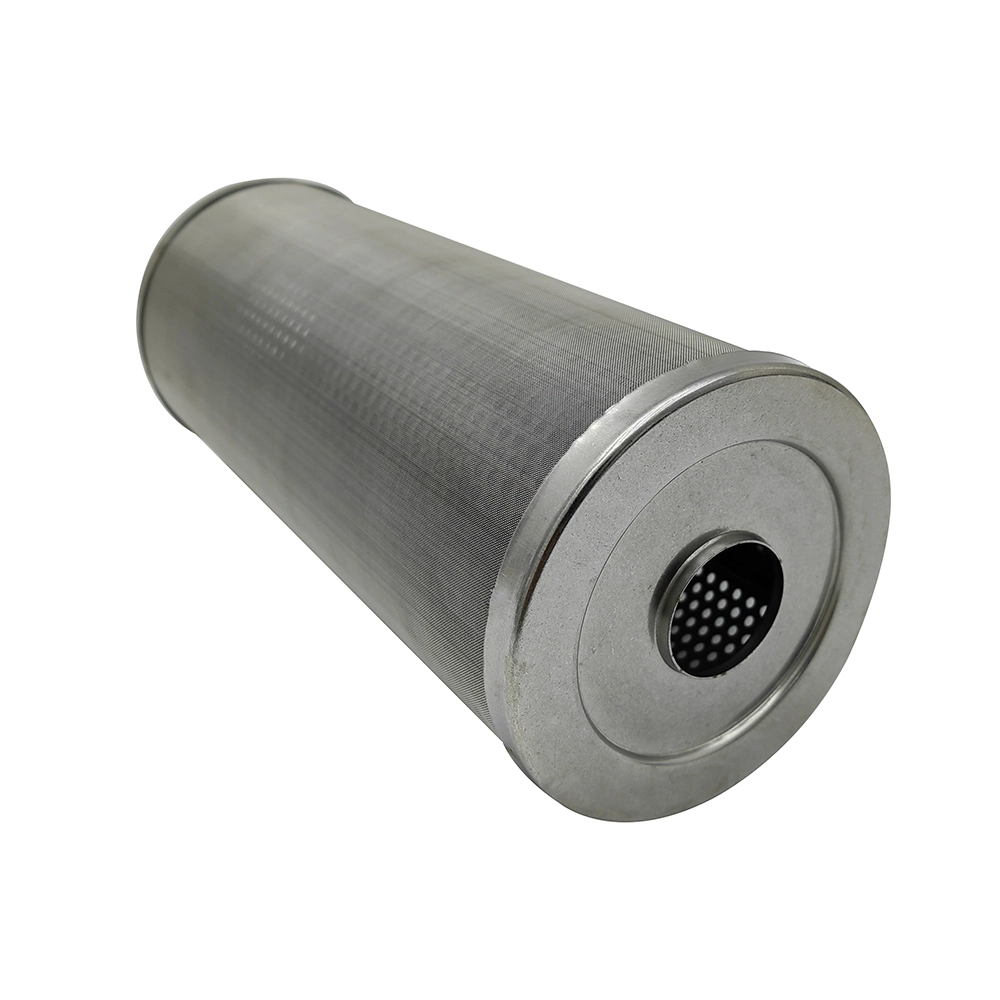

Sintered metal filter

Sintered powder metal filters

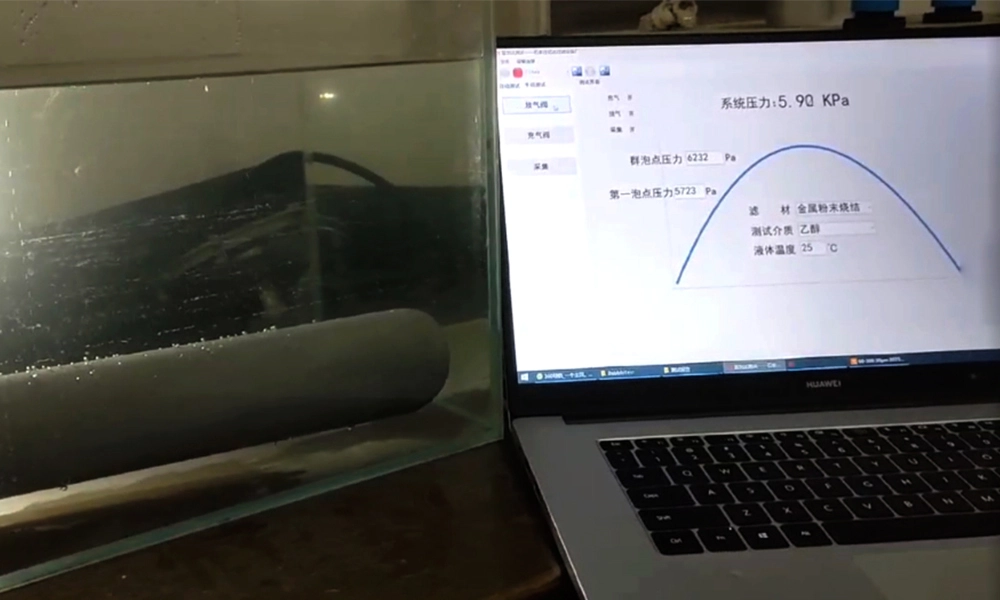

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Sintered powder metal filters

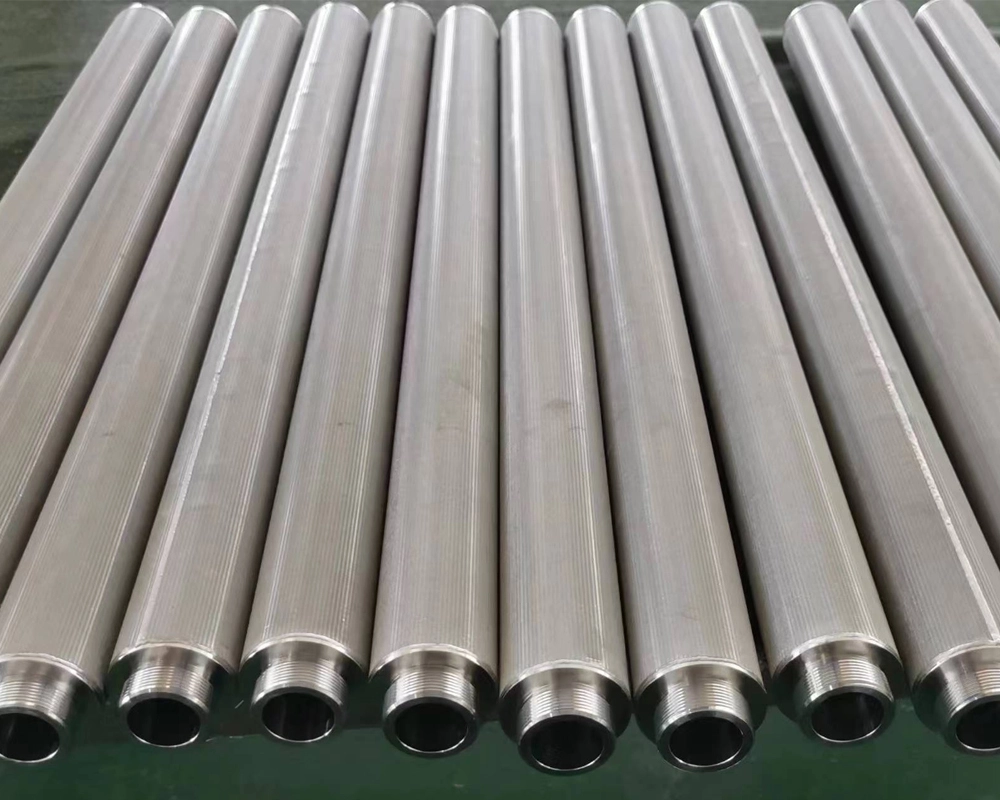

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sintered wire mesh filter

stainless steel filter water

Lvyuan’s sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

stainless steel filter water

Stainless steel pleated filter cartridge

Lvyuan Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

Stainless steel pleated filter cartridge

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

Sintered titanium filter

Sintered felt filter cartridge

Lvyuan sintered felt filter cartridge is processed using stainless steel fiber sintered felt, with the standard material being 316L. The finished felt is formed by different pore size layers to create a gradient density, allowing for controlled high filtration precision and dirt holding capacity.

Sintered felt filter cartridge

Sintered Porous Metal Filter Disc

Discover the epitome of precision filtration with our Sintered Porous Filter Discs at Lvyuan. As a leading provider of filtration solutions, we take pride in offering high-performance filter discs designed to meet the most stringent industrial requirements.

Sintered Porous Metal Filter Disc

Stainless steel perforated filter

Lvyuan stainless steel Perforated filter is a new type of filter material processed by combining perforated plates with several layers of square mesh (or dense mesh) through sintering.

Stainless steel perforated filterSintered Metal Filter Advantages

Sintered metal filters offer high filtration efficiency, strength, and durability. The materials exhibit resistance to temperature and corrosion, a uniform pore structure, customizable ratings, and low maintenance requirements. These characteristics contribute to their versatility in applications, chemical compatibility, and suitability for harsh environments, thereby ensuring their reliability for precise and efficient filtration.

Lvyuan: Your Leading Sintered Metal Filter manufacturer

Lvyuan sintered metal filters have developed a variety of products, including sintered metal powder filters, sintered mesh filters, sintered metal fiber felt filters, and more. In addition to the provision of these products, Lvyuan also supplies replacement sintered filter cartridges, which can be applied in a variety of fields. The company is committed to offering accurate filters with high filtration rates, whether the customer requires OEM size or specifies their own size. The company's sintered raw materials are produced to meet customers' specific filtration requirements while remaining affordable.

Has Obvious Advantages

In comparison with alternative metal filter cartridges, Lvyuan sintered filter cartridges are distinguished by the following characteristics. These filters are renowned for their high strength, durability, and reusability, and they demonstrate exceptional resistance to pressure, as the mesh remains undamaged even in challenging conditions. The selection of these sintered metal filters ensures a prolonged operational lifespan, thereby minimizing the frequency of replacement.

Provide Customized Services

In order to meet the precise requirements of customers, the option of customizing sintered metal filter elements is hereby presented. To facilitate this process, we request basic data pertaining to the desired element's shape, intended application, the manner of its installation, the flow rate, the pressure drop, the working pressure, the working temperature, and the material from which it is to be fabricated. Thereafter, a team of experienced engineers will design a custom solution for the client, providing a reference and choice that will satisfy the customer's filtration needs. By selecting Lvyuan, customers can be assured of a long-term and efficient filtration system that will be designed according to their specific needs.

Sintered Stainless Steel Filter

Lvyuan offers a variety of sintered stainless steel filters, including stainless steel sintered filter cartridges, sintered stainless steel plates, sintered stainless steel sheets, sintered stainless steel tubes, and sintered stainless steel filter discs. These filters are manufactured from high-quality stainless steel 304 and 316, thus providing high durability and reliability in many applications.

The performance and durability of the filter element are notable features of Lvyuan's sintered stainless steel filters. These filters find application in liquid and gas filtration processes and have gained a high level of popularity. The company's product range includes stainless steel sintered filter cartridges, offering filtration precisions ranging from 0.5 to 300 microns, a capacity to fulfill a broad spectrum of filtration requirements. These filters demonstrate robust functionality in extreme temperature ranges, operating effectively from -200°C to 1000°C, making them suitable for diverse industrial applications. For optimal performance and longevity, it is recommended to select Lvyuan's stainless steel sintered filters.

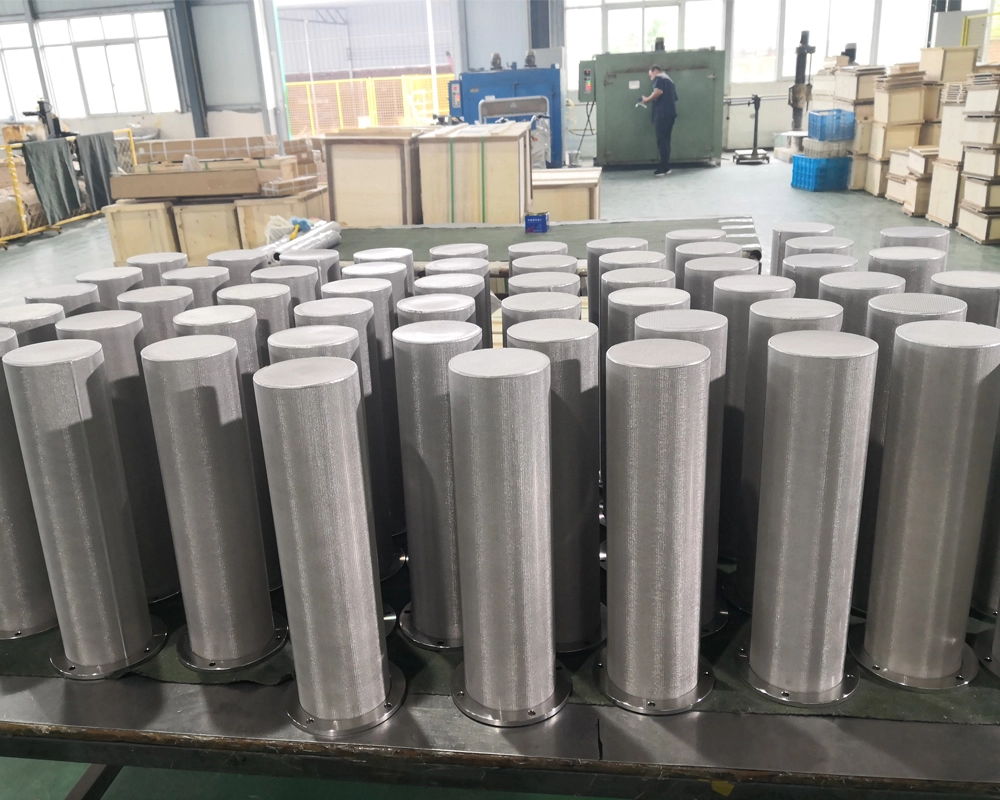

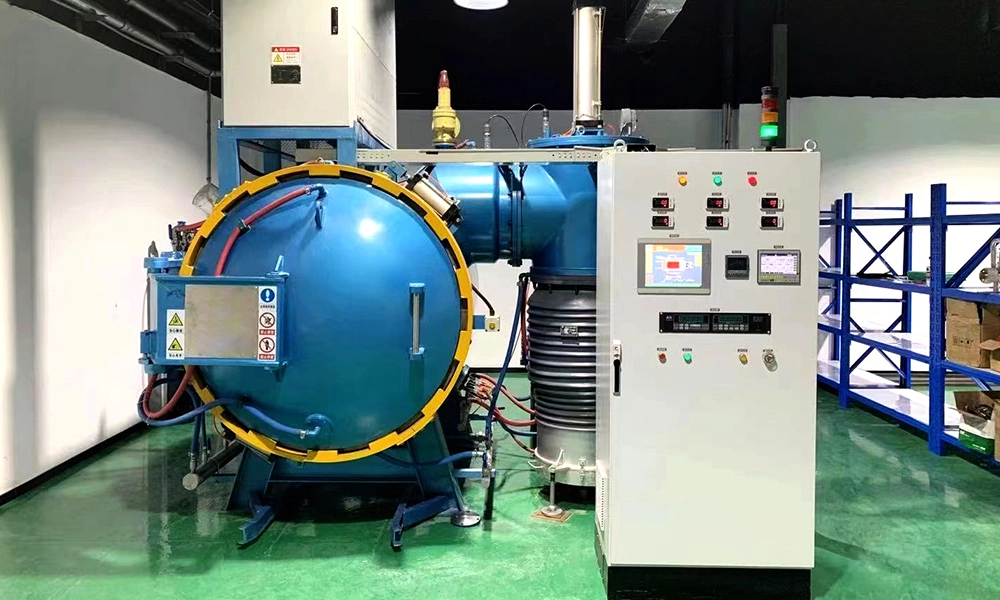

Production Processing of Sintered Metal Filter at Lvyuan

The manufacturing process of Lvyuan sintered metal filters is characterized by a stringent set of production steps. These include the processes of rolling, pressurizing, and vacuum sintering, which collectively result in the production of a filter characterized by a constant pore size and permeability.

At Lvyuan, the commitment to excellence in the production of sintered wire mesh is paramount, ensuring that each filter meets the highest standards of quality and performance.

Lvyuan Sintered Metal Filters Classification

Lvyuan's diverse sintered mesh filters are designed to meet a wide range of filtration requirements, with options available based on varied weaving techniques and materials. Each classification is designed to deliver optimal performance in specific applications, ensuring versatility and effectiveness in the user's filtration processes.

Perforated Plate with Multi-Layer Sintered Metal Filter

We’ve got answers.

Browse some answers to our most common questions, or you can drop us a line to ask something else.

Sintered Metal Filter

Can industrial sintered metal filter cartridges be customized?

Yes, these cartridges can be customized in terms of dimensions, filtration ratings, materials, and end connections to suit the specific needs of different industrial processes.

How often should industrial-sintered metal filter cartridges be replaced?

The replacement frequency depends on the operating conditions and the level of contaminants in the process. Regular inspection and monitoring help determine the optimal replacement schedule.

What is an industrial sintered metal filter cartridge?

An industrial sintered filter cartridge is a filtration component made through a sintering process, combining metal powders to create a porous structure. These cartridges are designed for industrial applications to remove contaminants from liquids and gases.

What materials are commonly used in industrial-sintered metal filter cartridges?

Common materials include stainless steel (304, 316, and 316L), bronze, Inconel, Monel, titanium, and other alloys, depending on the specific requirements of the application.

What are the key advantages of using industrial-sintered metal filter cartridges?

Advantages include high filtration efficiency, durability, wide temperature resistance, chemical compatibility, customization options, high flow rates, ease of cleaning, and versatility across various industries.

In which industries are industrial sintered metal filter cartridges commonly used?

These cartridges find applications in petrochemicals, pharmaceuticals, water treatment, food processing, automotive, aerospace, and many other industries where precise and reliable filtration is essential.

What is the temperature range that industrial sintered metal filter cartridges can handle?

The temperature range varies based on the material used, but they can typically withstand temperatures from -200°C to 1000°C or even higher for certain alloys.

How often should industrial sintered metal filter cartridges be replaced?

The replacement frequency depends on the operating conditions and the level of contaminants in the process. Regular inspection and monitoring help determine the optimal replacement schedule.

Are industrial sintered metal filter cartridges environmentally friendly?

Yes, these cartridges are environmentally friendly due to their reusability and longer lifespan, contributing to reduced waste generation compared to disposable filters.

What is the cleaning process for industrial sintered metal filter cartridges?

Cleaning methods include backwashing, ultrasonic cleaning, chemical cleaning, or a combination of these, depending on the type of contaminants and the cartridge material.

Want to talk to us

Get in touch

Please fill in the form below. We aim to reply within 1 business day.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions