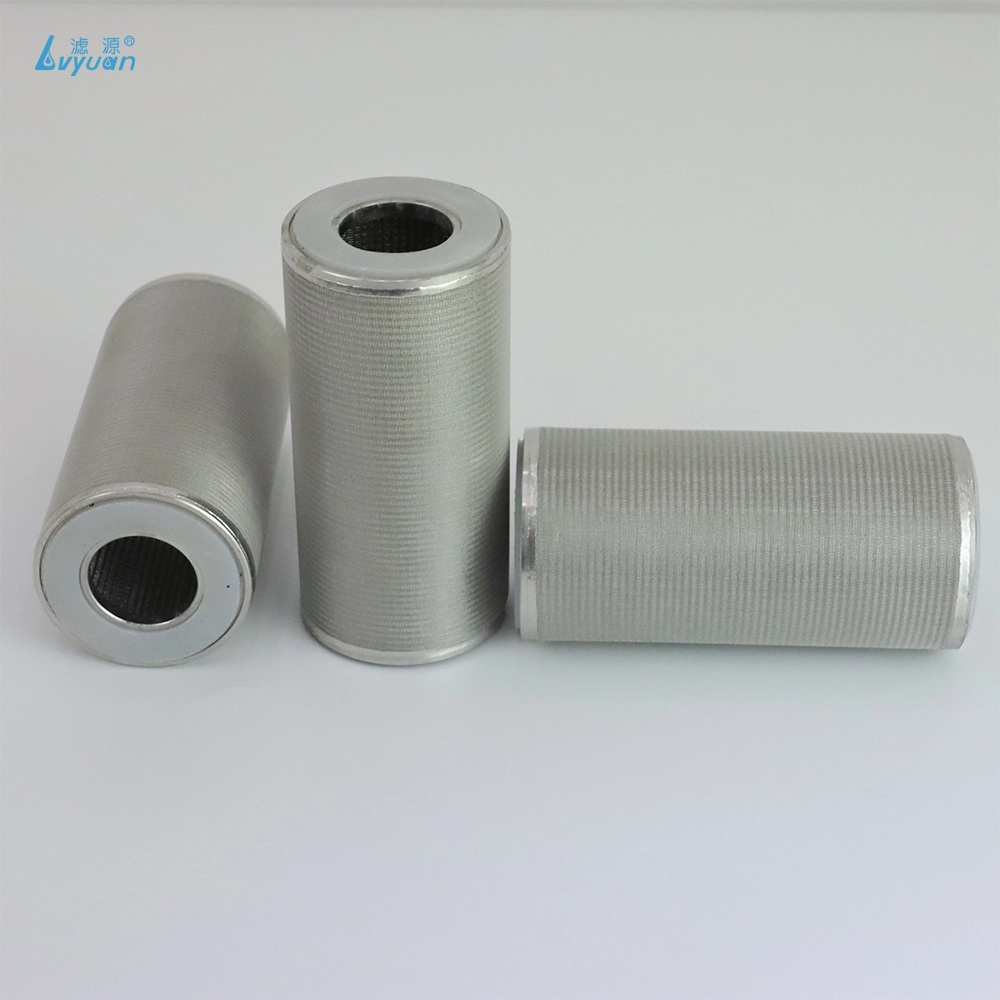

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

![]() Personalized customization:

Personalized customization:

Whether choosing from these specifications or presenting your unique requirements, Lvyuan ensures a tailored approach to meet your specific needs.

![]() After-Sales Service and Warranty:

After-Sales Service and Warranty:

We offer comprehensive after-sales services, including installation guidance and technical support. Our products also come with a specified warranty period to ensure a worry-free experience for our customers.

Leading metal mesh filters Manufacturer

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Recognized as one of the premier metal mesh filter manufacturers in China, Lvyuan proudly holds various certifications, including ISO 9001 and CE. Our commitment to quality is reflected in our sintered metal mesh, which has gained popularity in over 30 countries. We prioritize delivering sintered mesh products that combine exceptional quality with competitive pricing.

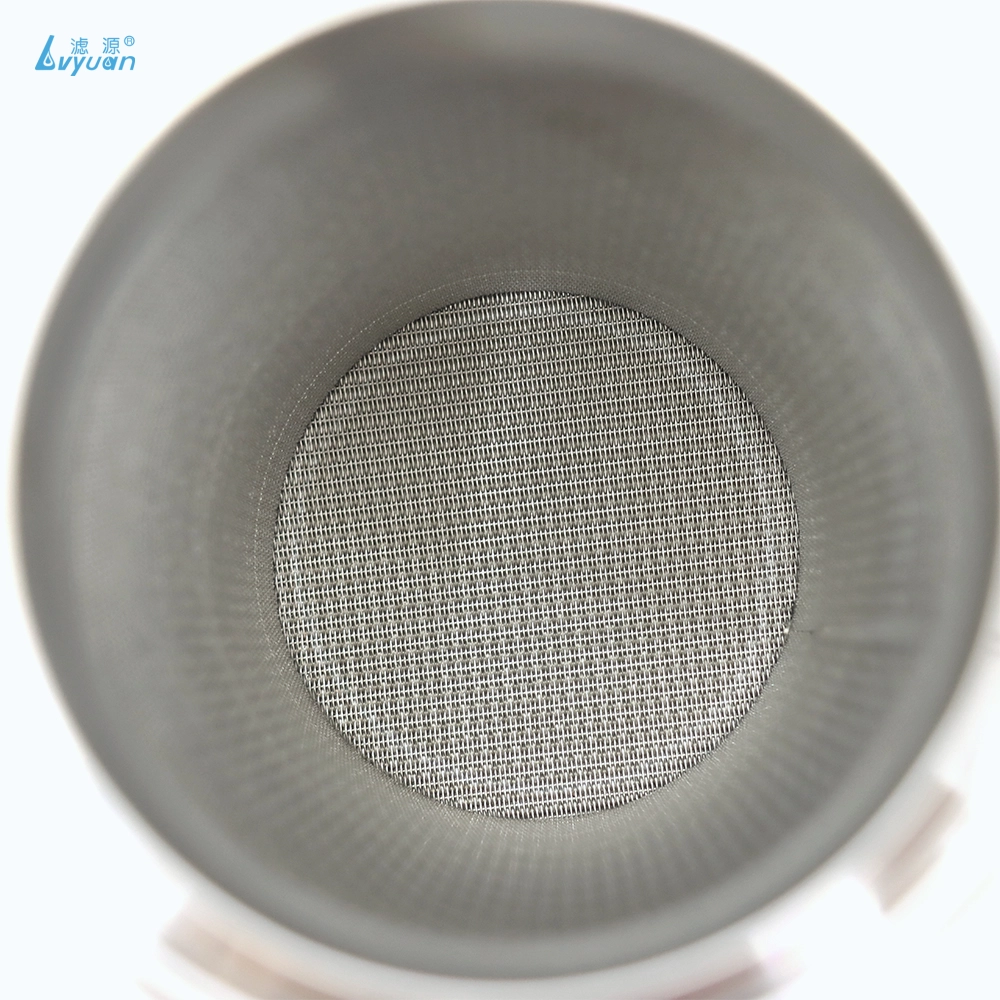

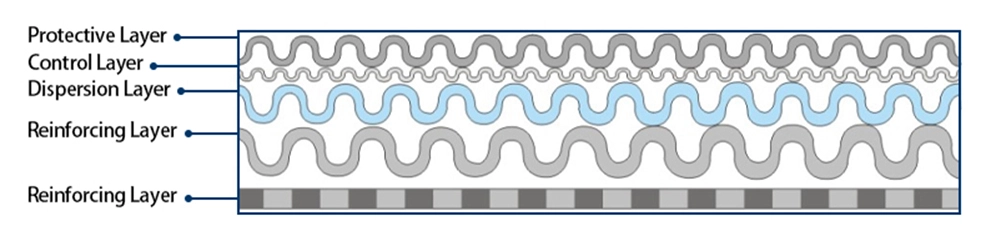

5 layers sintered mesh

The standard five-layer sintered mesh structure consists of four parts: a protective layer, a filter layer, a dispersion layer, and a skeleton layer. This filter material offers both uniform and stable filtration precision, as well as high strength and rigidity. It is ideal for applications requiring high compressive strength and uniform filtration precision.

Due to its surface filtration mechanism and smooth mesh channels, it exhibits excellent backwashing and regeneration performance, allowing for long-term, repeated use. Particularly suitable for continuous and automated operation processes, it surpasses any other filtering material.

This material is easy to shape, process, and weld, making it convenient to manufacture into various forms of filter elements such as round, cylindrical, conical, and corrugated.

Product Feature

• Good strength and rigidity: exhibits excellent mechanical strength and pressure resistance, with good processing, welding, and assembly properties, making it easy to use.

• Uniform and stable precision: achieves consistent filtration performance with uniform precision, with no change in mesh size during use.

• Wide range of applications: suitable for filtration in environments ranging from -200°C to 600°C and in acidic or alkaline conditions.

• Excellent cleaning performance: offers excellent backwashing effects, allowing for repeated use and a long lifespan (can be cleaned using backflow water, filtrate, ultrasonic waves, melting, baking, etc.).

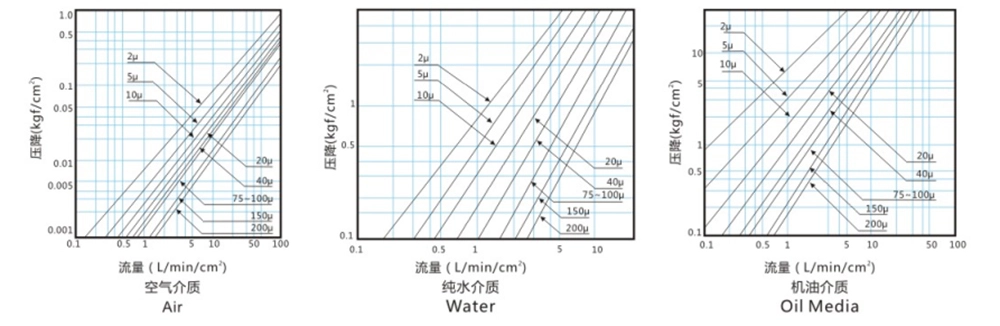

Product pressure drop flow characteristics

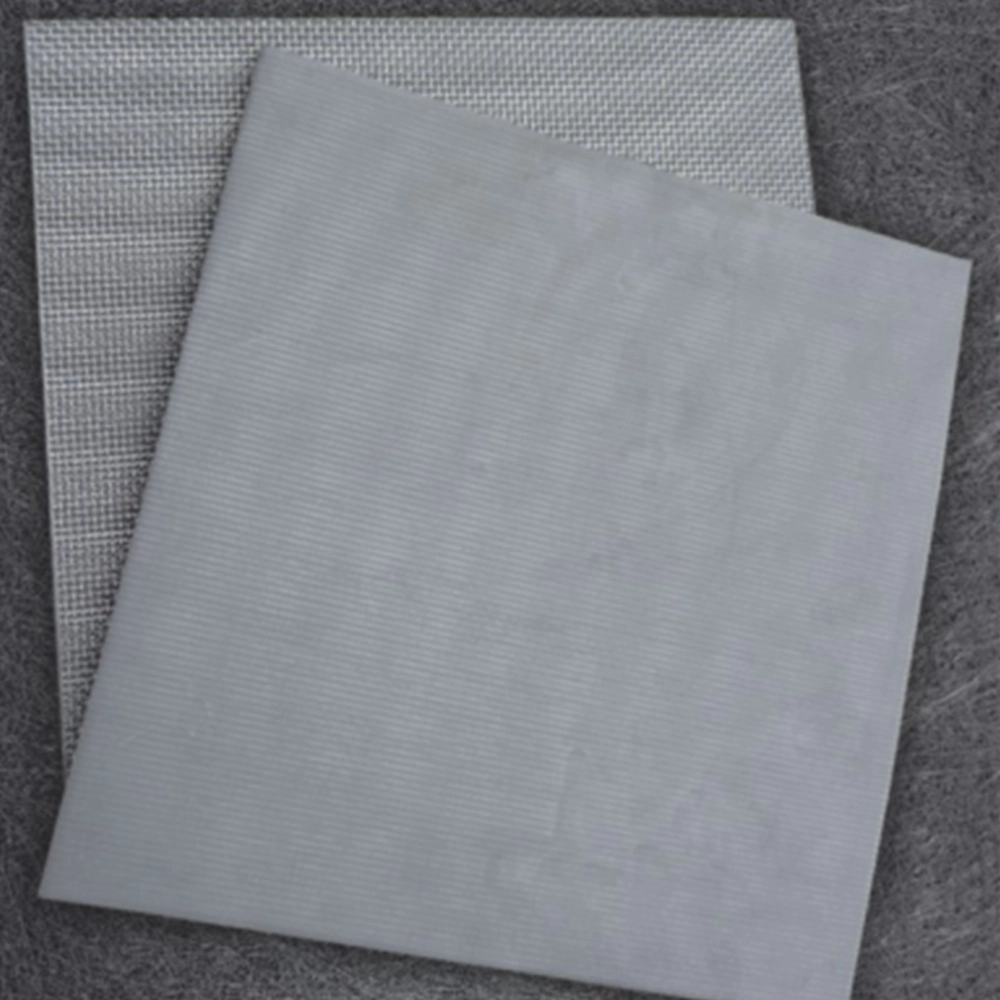

6 layers sintered mesh

The six-layer metal sintered mesh is a new type of filtering material made by special layering and pressing of six layers of stainless steel wire mesh and then sintered under vacuum. It has high strength and overall rigidity.

The mesh of each layer is interlaced with each other, forming a uniform and ideal filtering structure. It has the characteristics of high filtration precision, low filtration impedance, good mechanical strength, wear resistance, heat resistance, cold resistance, and excellent process ability.

It is particularly ideal for applications requiring high compressive strength and uniform filtration precision and is widely used in the food and pharmaceutical industries, especially in pharmaceutical two-in-one and three-in-one equipment.

Product Specifications

• Standard Material: SUS304, SUS316L.

• Dimensions: 1000mm * 500mm, 1000mm * 600mm, 1000mm * 1000mm, 1200mm * 1000mm, 1200mm * 1200mm.

• Filtration precision: 1~300 micrometers.

• Special materials (such as Monel alloy, 904L) and dimensions can be supplied according to customer requirements.

Product description

Adding an extra layer of 8-mesh or 12-mesh square-hole mesh behind the standard five-layer mesh creates a six-layer sintered mesh. It offers better strength and diversion performance compared to the standard five-layer mesh.

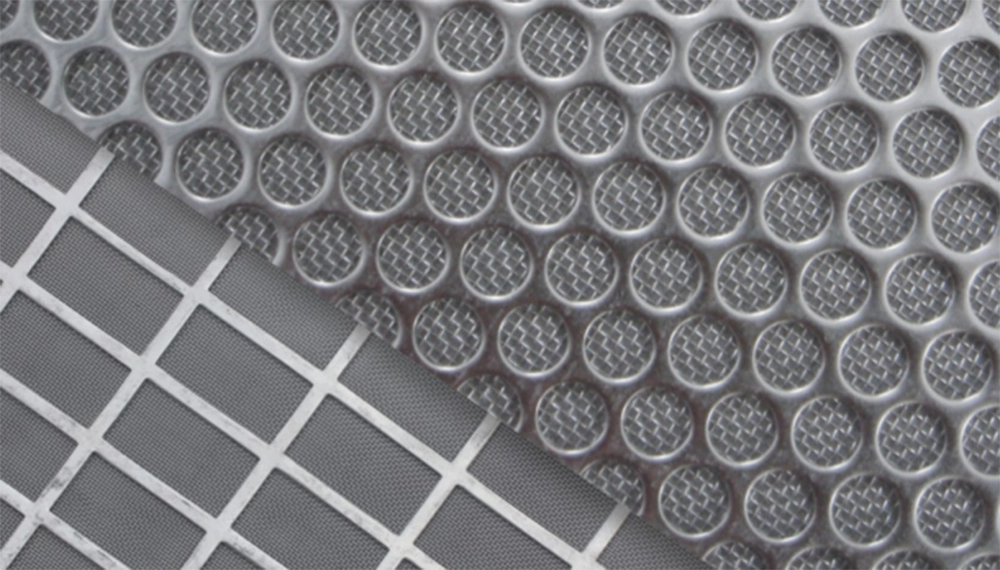

Perforated plate composite sintered mesh

This is a new type of filter material composed of standard materials (stainless steel 304, 2205, 2507, 904L, or 316L) punched plates combined with several layers of square-hole mesh (or dense weave mesh) and sintered together.

The number of layers and the mesh size are determined based on different usage conditions and purposes.

Structure diagram

Product Features

Due to its integration of a pressure-resistant framework and filter mesh through sintering, it possesses higher mechanical strength, an excellent backwashing effect, and minimal pressure drop loss.

Product Applications

It has been widely used in the water treatment, beverage, food, metallurgy, chemical, and pharmaceutical industries.

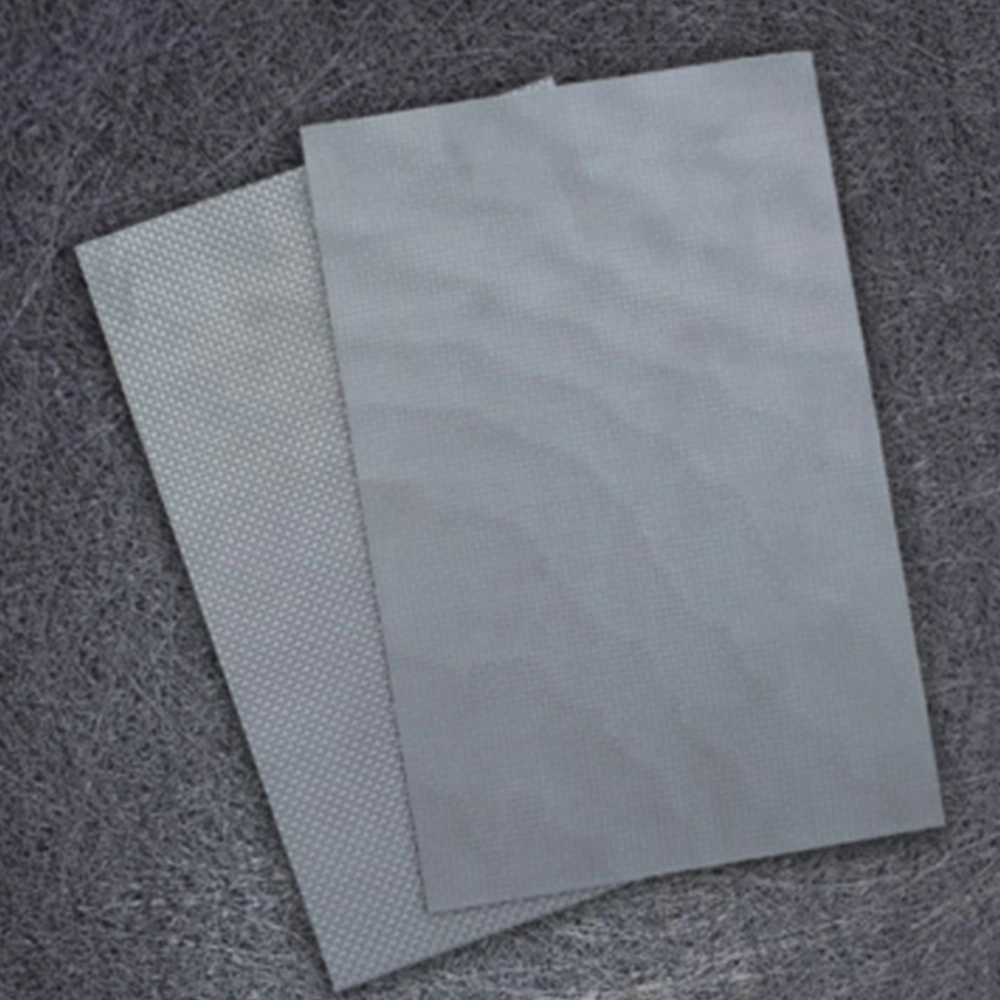

Multi-layers sintered mesh

Multi-layer metal sintered mesh is a new type of filtering material made by special layering and pressing of multiple layers of stainless steel wire mesh, sintered under vacuum, providing high strength and overall rigidity.

The meshes of each layer are interlaced with each other, forming a uniform and ideal filtering structure. It boasts excellent filtration precision, low filtration impedance, mechanical strength, wear resistance, heat resistance, cold resistance, and processability.

It is particularly ideal for applications requiring high compressive strength and uniform filtration precision, widely used in petrochemical, nuclear power, synthetic fiber, film, food, pharmaceutical, aerospace, and environmental protection industries.

Product Specifications

• Standard Materials: SUS304, SUS316L, 2205, 2507, 904L.

• Standard Dimensions: 1000mm500mm, 1000mm600mm, 1000mm1000mm, 1200mm1000mm, 1200mm*1200mm.

• Filtration Precision: 1-300 micrometers.

• Special specifications can be provided according to customer requirements.

Main Applications

Adding an extra layer of 8-mesh or 12-mesh square-hole mesh behind the standard five-layer mesh creates a six-layer sintered mesh. It offers better strength and diversion performance compared to the standard five-layer mesh.

Application Fields

• Precision filtration of various hydraulic oils and lubricants in the mechanical industry.

• Filtration and purification of various polymer melts in the chemical fiber membrane industry.

• Filtration of various high-temperature and corrosive liquids in the petrochemical industry; filtration, washing, and drying of materials in the pharmaceutical industry.

• Application in gas uniformization in the powder industry; fluidized plates in the steel industry.

• Use explosion-proof appliances, such as alarm bells in explosion-proof electrical appliances.

Why Choose Lvyuan?

How to clean metal mesh filters?

Steps:

Tips:

We’ve got answers.

Browse some answers to our most common questions, or you can drop us a line to ask something else.

Metal mesh filters

What is sintered wire mesh filter?

Sintered wire mesh is a porous metal filtration material created by sintering multiple layers of woven wire mesh. The sintering process bonds the wires at their intersection points, creating a durable and uniform structure with precise filtration characteristics.

What are the key advantages of sintered wire mesh filter?

• High Strength: The sintered wire mesh filter exhibits excellent mechanical strength.

• Uniform Porosity: The sintering process creates a uniform pore structure for efficient filtration.

• Temperature Resistance: Suitable for applications with high temperatures.

• Easy to Clean: Can be cleaned and reused multiple times.

• Chemical Resistance: Resistant to corrosion and chemical exposure.

How is sintered wire mesh filter different from woven wire mesh filter?

While both types involve woven wires, sintered wire mesh undergoes an additional sintering process. This process fuses the wires together, creating a rigid and porous structure. Woven wire mesh relies on the mesh's openings for filtration, while sintered mesh utilizes the entire structure for efficient filtration.

What applications is sintered wire mesh suitable for?

Sintered wire mesh filter finds applications in various industries, including:

• Filtration of liquids and gases.

• Polymer and chemical processing.

• Pharmaceutical and food processing.

• Aerospace and automotive industries.

• Environmental protection and water treatment.

Sintered Metal Filter

Are industrial sintered metal filter cartridges environmentally friendly?

Yes, these cartridges are environmentally friendly due to their reusability and longer lifespan, contributing to reduced waste generation compared to disposable filters.

What is the cleaning process for industrial sintered metal filter cartridges?

Cleaning methods include backwashing, ultrasonic cleaning, chemical cleaning, or a combination of these, depending on the type of contaminants and the cartridge material.

Want to talk to us

Get in touch

Please fill in the form below. We aim to reply within 1 business day.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

stainless steel filter water

Lvyuan’s sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless steel pleated filter cartridge

Lvyuan Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

Sintered titanium filter

Discover the efficiency and versatility of Lvyuan's sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions