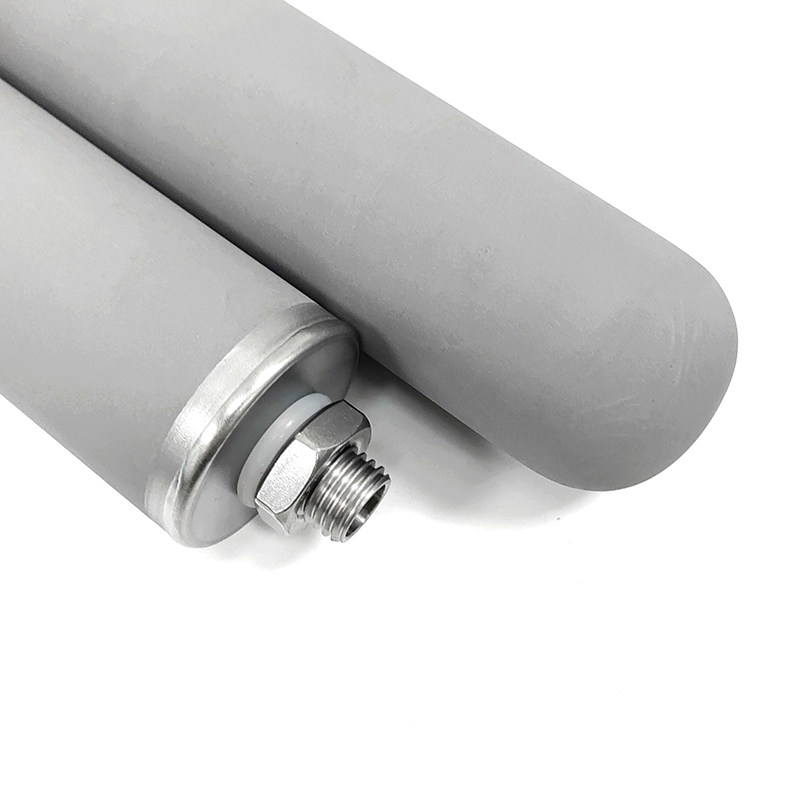

Lvyuan Porous Titanium Filter Cartridges - Superior Filtration Solution.

Discover the exceptional capabilities of Lvyuan Porous Titanium Filter Cartridges, the solution for your filtration needs. Engineered with precision, these filter cartridges offer unparalleled filtration efficiency thanks to their advanced porous titanium structure. Each cartridge is crafted to provide superior mechanical strength and durability, making them ideal for a wide range of applications, from water filtration systems to chemical processing plants.

What sets Lvyuan Porous Titanium Filter Cartridges apart is their unique design and unique advantages. The porous titanium structure allows for high permeability and minimal pressure drop, ensuring an uninterrupted flow of liquids or gases. This design also provides remarkable thermal stability, making these cartridges suitable for high-temperature environments. Furthermore, their corrosion-resistant nature guarantees long-lasting performance, reducing the need for frequent replacements and ly saving you money.

In addition to their robust performance, Lvyuan Porous Titanium Filter Cartridges are environmentally friendly and easy to clean. Their reusability not only reduces waste but also promotes sustainability in your filtration processes. Whether you are looking to enhance the purity of your water supply or improve the efficiency of your industrial systems, Lvyuan offers a reliable and effective solution.

Choose Lvyuan Porous Titanium Filter Cartridges to experience the perfect blend of innovation and reliability. Transform your filtration systems today and benefit from the superior technology designed to meet the demands of modern industries. Join countless satisfied customers who have made these cartridges their go-to choice for efficient and sustainable filtration.

Picture Show

Advantages

Long Operational Lifespan

Sinter metal filters can be used for an extended period without frequent replacement. With good backwash performance, they can remain in operation for up to 10 years, reducing maintenance requirements and associated costs.

Safety and Environmental Protection

The use of sinter metal filters contributes to the reduction of safety risks and environmental impact. Their efficient filtration capabilities help maintain a clean and sterile environment in medical processes, ensuring the safety of patients and the protection of the environment.

High-Temperature Resistance

Carbonate hardness optimization. Ions forming scales are removed.

Hygienic Design

Sintered metal filters are designed with materials that meet food-grade hygiene standards. They are easy to clean and sanitize, preventing bacterial contamination and ensuring compliance with industry regulations.

FAQ

Do Sintered Titanium Filters Offer High Flow Rates?

Yes, sintered titanium filters support high flow rates at low-pressure drops, optimizing efficiency and ensuring consistent filtration performance.

What is a sintered mesh filter?

A sintered mesh filter is a porous metal filter element made by sintering multiple layers of woven wire mesh. It provides effective filtration for various applications, offering advantages such as durability, temperature resistance, and customizable filtration ratings.

How do I choose the right sintered metal filter for my application?

To select the appropriate sintered metal filter, consider factors such as the type of fluid or gas, desired flow rate, temperature, pressure, and particle size to be filtered. Our technical team can provide guidance based on your specific requirements.

How to Calculate Filter Porosity?

Filter porosity is classified into three major types: Primary Porosity, Secondary Porosity, and Effective Porosity. The calculation involves determining the ratio of the volume of gaps in the filter to the total volume, expressed as a percentage.

Porosity = (Volume of Empty Gaps/Total Volume of Filter) x 100

Other methods include:

• Direct Methods: Calculate the entire volume of the porous filter and the volume of a skeletal filter (without pores) to find the porosity.

• Computed Methods: Use modern computer technology to obtain a 3D image of a porous filter and employ defect analysis techniques.

• Water Evaporation Technique: Calculate porosity by determining the difference in weight between the saturated filter in water and the dried filter.

Stainless steel air filter housing

Sintered felt filter cartridge

Sanitary filter housing

customized size Flanged Stainless Steel Basket Strainer precision filtration

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions