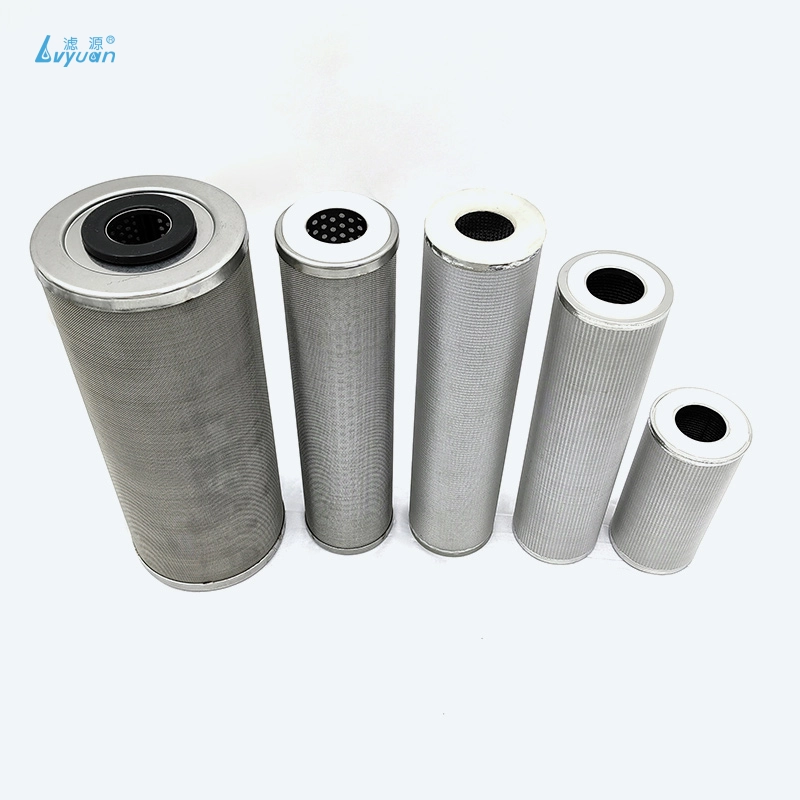

Sintered metal filter cartridge

Lvyuan specializes in the production of high-quality industrial-sintered metal filter cartridges. These cartridges are meticulously crafted using advanced sintering techniques and premium materials, ensuring durability and optimal performance in various industrial applications.

![]() Personalized customization:

Personalized customization:

Whether choosing from these specifications or presenting your unique requirements, Lvyuan ensures a tailored approach to meet your specific needs.

![]() After-Sales Service and Warranty:

After-Sales Service and Warranty:

We offer comprehensive after-sales services, including installation guidance and technical support. Our products also come with a specified warranty period to ensure a worry-free experience for our customers.

Details of Sintered metal filter cartridges

-

Material Options:

- • Stainless Steel: 304, 316L

- •Other Metals: Nickel, Titanium, Bronze, Inconel, Hastelloy

-

Filtration Rating:

- • Pore Size: 0.2 µm to 100 µm

- •Micron Rating: As per application requirements

-

Dimensions:

- •Diameter: Common sizes range from 10 mm to 200 mm

- •Length: Available from 50 mm to 1500 mm or custom sizes

-

Pressure Rating:

- • Maximum Operating Pressure: Up to 5 MPa (725 psi)

- •Burst Pressure: Higher than operating pressure, varies by design

-

Connection Types:

- • End Connections: Threaded, Flanged, Welded, Quick Connect

- •Fittings: NPT, BSP, Flanged, Clamp

-

Surface Area:

- •Filter Surface Area: Varies by design, affects filtration efficiency

-

-

Customization:

- • Sizes and Shapes: Tailored to specific application requirements

- •Material Composition: Altered to meet chemical compatibility and environmental needs

Industrial sintered filter cartridge

Lvyuan sintered metal filters are designed for superior filtration performance in industrial settings. Whether you need precise filtration for liquids or gases, our industrial sintered filter cartridges deliver reliable results. With a focus on quality and efficiency, our filters are ideal for a wide range of industrial applications.

The sintered metal filter cartridges exhibit excellent filtration efficiency, corrosion resistance, andthe ability to withstand challenging operating conditions. With a commitment to precisionengineering, Lvyuan delivers reliable filtration solutions tailored to meet the diverse needs ofindustries such as petrochemicals, water treatment, pharmaceuticals, and more. Trust Lvyuan fortop-notch industrial sintered metal filter cartridges that elevate filtration standards.

Sintered metal filter cartridges

Our sintered metal filter cartridges are crafted from five or multiple layers of stainless steel wire mesh, subjected to high-temperature sintering and advanced processing. Alternatively, it can be manufactured using a folding process, endowing it with excellent permeability, strong pollutant retention capability, large filtration area, long lifespan, high-temperature and corrosion resistance, reusability through cleaning, and other remarkable features.

It finds widespread applications in filtration systems within industries such as petroleum, chemicals, and more.

Primary Connection Methods

• Standard interfaces (such as 222, 220, 226)

• Quick interface connections

• Threaded connections

• Flange connections

• Rod connections

• Customized connections

Product advantages

Application Areas

Used for the filtration of polyester, water treatment, oils, pharmaceuticals, food and beverages, chemicals, filtration of synthetic fiber products, and high-temperature air, among other mediums.

We’ve got answers.

Browse some answers to our most common questions, or you can drop us a line to ask something else.

Sintered Metal Filter

Can industrial sintered metal filter cartridges be customized?

Yes, these cartridges can be customized in terms of dimensions, filtration ratings, materials, and end connections to suit the specific needs of different industrial processes.

How often should industrial-sintered metal filter cartridges be replaced?

The replacement frequency depends on the operating conditions and the level of contaminants in the process. Regular inspection and monitoring help determine the optimal replacement schedule.

How can I select the right industrial sintered filter cartridge for my application?

Consult with the manufacturer or supplier, providing details about your specific requirements, such as filtration needs, operating conditions, and industry standards, to receive guidance on selecting the most suitable cartridge for your application.

What is an industrial sintered metal filter cartridge?

An industrial sintered filter cartridge is a filtration component made through a sintering process, combining metal powders to create a porous structure. These cartridges are designed for industrial applications to remove contaminants from liquids and gases.

What materials are commonly used in industrial-sintered metal filter cartridges?

Common materials include stainless steel (304, 316, and 316L), bronze, Inconel, Monel, titanium, and other alloys, depending on the specific requirements of the application.

What are the key advantages of using industrial-sintered metal filter cartridges?

Advantages include high filtration efficiency, durability, wide temperature resistance, chemical compatibility, customization options, high flow rates, ease of cleaning, and versatility across various industries.

What is the cleaning process for industrial sintered metal filter cartridges?

Cleaning methods include backwashing, ultrasonic cleaning, chemical cleaning, or a combination of these, depending on the type of contaminants and the cartridge material.

Are industrial sintered metal filter cartridges environmentally friendly?

Yes, these cartridges are environmentally friendly due to their reusability and longer lifespan, contributing to reduced waste generation compared to disposable filters.

How often should industrial sintered metal filter cartridges be replaced?

The replacement frequency depends on the operating conditions and the level of contaminants in the process. Regular inspection and monitoring help determine the optimal replacement schedule.

Want to talk to us

Get in touch

Please fill in the form below. We aim to reply within 1 business day.

Bag filter housing

Bag filter housings are essential components in industrial filtration systems, designed to remove contaminants from liquids. To enhance the functionality and efficiency of bag filter housings, various features can be incorporated.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Stainless steel multi cartridge filter housing

Discover unparalleled filtration efficiency with our Stainless Steel Multi Cartridge Filter Housing – a testament to precision engineering and reliability.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

stainless steel filter water

Lvyuan’s sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Sanitary filter housing

This filter housing will allow you to filter large volumes of nanoemulsion with ease. Sanitary vent and drain valves permit easy venting, draining, sampling, or integrity testing operations. The new cartridge locking design features additional cut-outs for traditional half-moon portions of the Code 7 bayonet locks, enhancing clean ability and drain ability.

Stainless steel pleated filter cartridge

Lvyuan Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions