Sintered PTFE Filter

The sintered PTFE filter is a high-performance filtration solution designed to effectively remove impurities and contaminants from fluids, offering exceptional chemical resistance and durability in various industrial applications.

![]() Personalized customization:

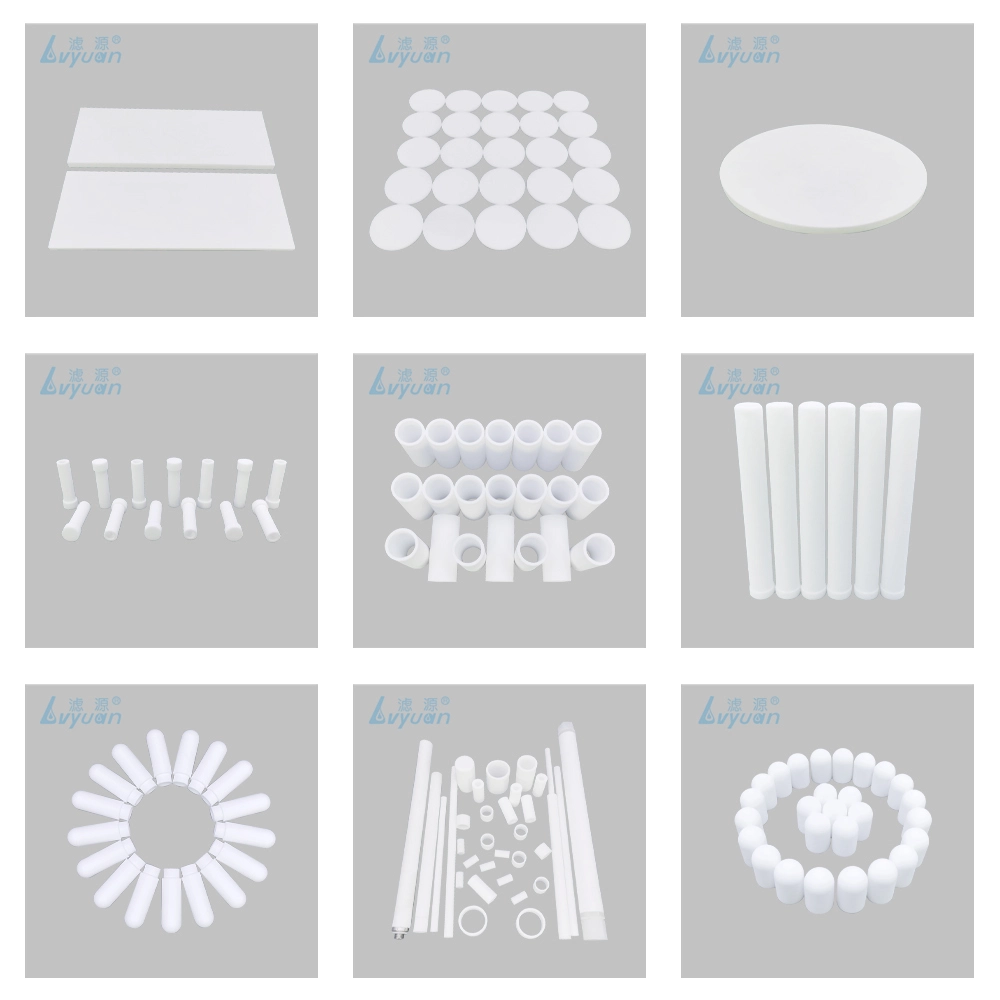

Personalized customization:

Whether choosing from these specifications or presenting your unique requirements, Lvyuan ensures a tailored approach to meet your specific needs.

![]() After-Sales Service and Warranty:

After-Sales Service and Warranty:

We offer comprehensive after-sales services, including installation guidance and technical support. Our products also come with a specified warranty period to ensure a worry-free experience for our customers.

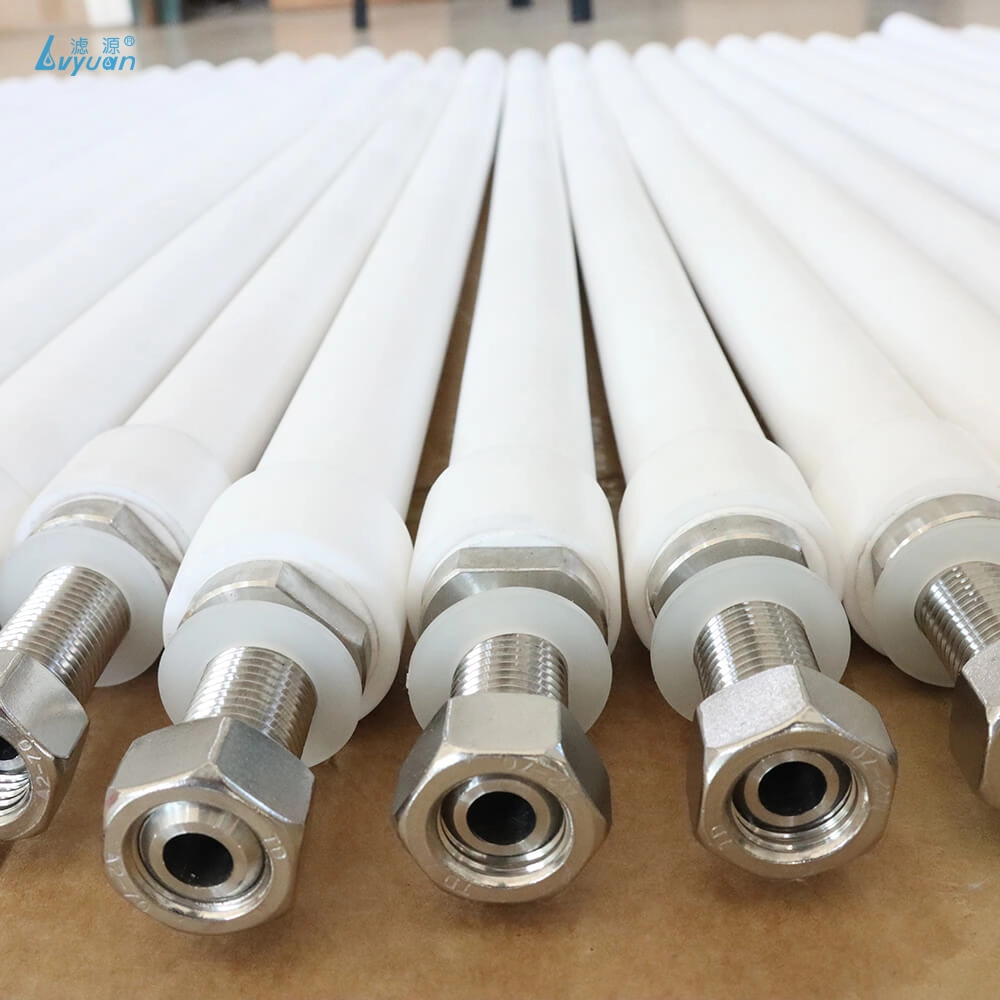

Product description

The surface of the cartridge is smooth, with high strength and good inutility, and the phenomenon of powder falling off will not occur. It is also extremely stable for all chemical substances. The material cartridge has a high porosity of more than 50% and a uniform pore size distribution. The cartridge has the ability to resist strong acid, strong alkali, chemical corrosion, "ozone," and various solvents, and can resist high temperatures up to 200 °C. It is widely used in the filtration of high-temperature gases, chemical liquids and other media.

Specifcation

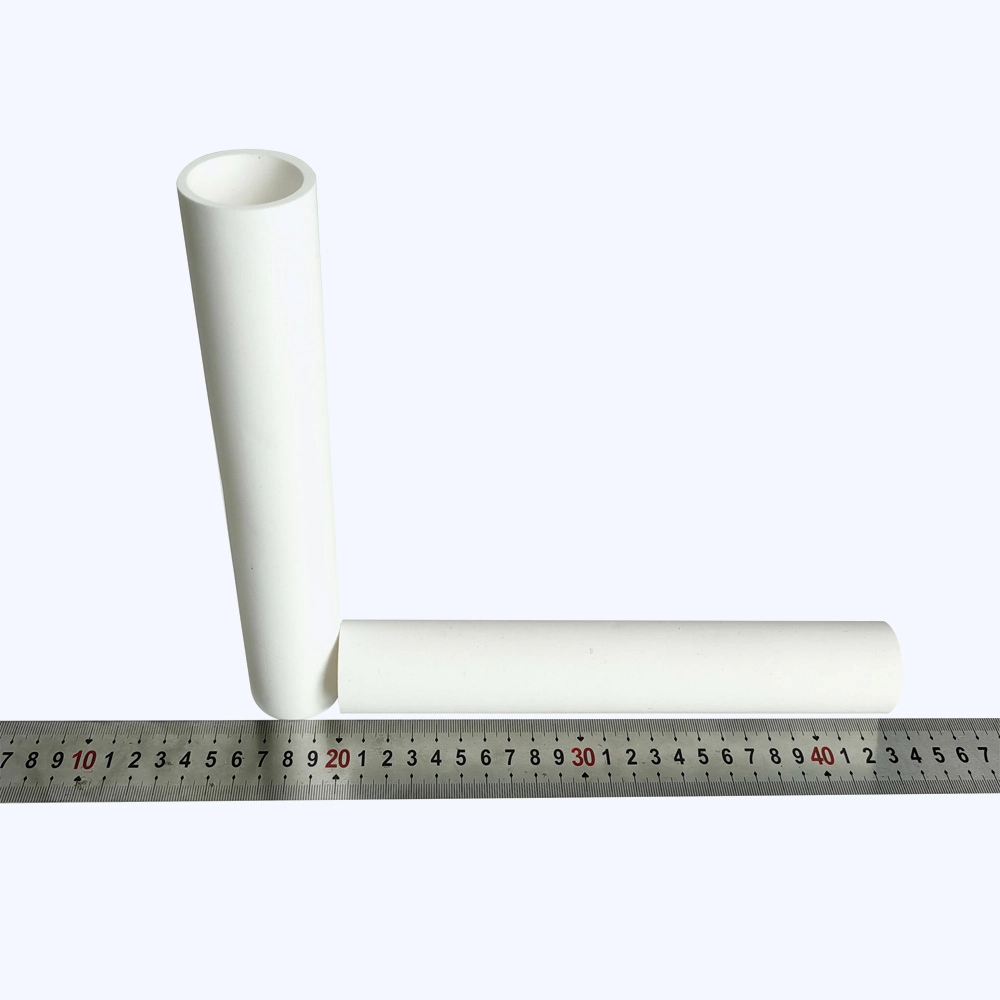

Regular size (mm):

31x12x1000, 31x20x1000, 38x20x1000, 38x18x1000, 38x20x1200, 38x20x1300, 38x20x150, 38x20x500, 38x20x400, 38x20x250, 38x20x200, 38x20x180, 38x20x150, 50x20x1000, 50x31x1000, 50x38x1000, 65x31x1000, 65x38x1000, 65x44x1000, 78x62x750

Outer diameter:

10mm, 20mm, 30mm, 40mm, 50mm, 60mm, 70mm, 80mm, 90mm, 100mm, 110mm, 120mm, 200mm, or customized by customer's request.

Inner diameter:

1.1"(28mm), or customized by customer's request.

Sintered PTFE Filter Product Features

Material of constructions

Filter media: PTFE (Polytetrafluoroethylene)

Connector type: Flat, Insert type, thread type, Fin

End caps: PP, M36, M30, M25, M22, M14, and M12

Performance

Removal rating: 0.3um 0,45um 1um 3um 5um 10um 20um 30um 40um 50um

Maximum Operating Temperature:2200'℃

Maximum Operating Pressure: 6.0bar

Parameters

• Material: ultra-high-polymer polytetrafluoroethylene

• Application: for strong acid, strong alkalis, high temperatures, and chemical corrosion

• Scope of application: air, water, liquid, or oil

• General working pressure difference: 5bar

• Filtration precision: 1-100um

• Working temperature:≤200 "C

We’ve got answers.

Browse some answers to our most common questions, or you can drop us a line to ask something else.

Porous Plastic Filter

How do I integrate sintered porous filter discs into my filtration system?

They are designed for easy integration into existing filtration systems. The compact design allows for straightforward installation and replacement.

How do I clean and maintain sintered plastic porous filters?

Sintered plastic porous filters can be cleaned using various methods, such as backwashing, ultrasonic cleaning, chemical cleaning, and steam sterilization, depending on the type of contaminants and the filter's compatibility with cleaning agents. Regular maintenance, such as inspection and replacement of filters, is essential to ensuring optimal performance.

Can sintered plastic porous filters be customized?

Yes, sintered plastic porous filters can be customized to meet specific application requirements, including pore size, shape, dimensions, and surface properties. Customizations may also include the addition of additives or reinforcements for enhanced performance.

Are sintered porous filter discs suitable for sterile filtration?

Yes, sintered porous filter discs can be designed for sterile filtration applications, especially when made from materials suitable for high-temperature and chemical sterilization methods.

What is a sintered plastic porous filter?

A sintered plastic porous filter is a filtration device made from polymeric materials that are compressed and heated to form a porous structure with controlled pore sizes and distribution.

What are the benefits of using sintered plastic porous filters?

Sintered plastic porous filters offer several advantages, including chemical resistance, high temperature resistance, compatibility with a wide range of fluids, uniform pore size distribution, and excellent filtration efficiency.

Want to talk to us

Get in touch

Please fill in the form below. We aim to reply within 1 business day.

Sintered PE Filter

Lvyuan Sintered polyethylene PE pipe or plate can be used for vacuum filtration, pressure filtration or gravity filtration.

PA Filter

Sintered PA filter cartridge is made of high quality polymer polyethylene as the main raw material and carbon fiber sintered by scientific formula. It is compact, sturdy, light and can withstand high pressure, non-toxic and tasteless, and has good corrosion resistance to acid and alkali.

Sintered PTFE Filter

The sintered PTFE filter is a high-performance filtration solution designed to effectively remove impurities and contaminants from fluids, offering exceptional chemical resistance and durability in various industrial applications.

Sintered PP Filter

High-quality polypropylene(PP) is used as the main raw material and sintered by scientific formula, which is compact, strong, light and can withstand high filtration pressure, and the aperture of the cartridge is the same inside and outside, so it is easy to blow back and de-flow, and has good corrosion resistance to acid and broken solvent.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions