Sintered Polypropylene - Unmatched Strength and Durability

Introducing our revolutionary Sintered Polypropylene product, designed to deliver unparalleled performance and durability. Made with cutting-edge technology, our Sintered Polypropylene offers a unique combination of strength, heat resistance, and chemical inertness. Whether you're looking for a material for automotive components, industrial filters, or consumer goods, our Sintered Polypropylene is the perfect choice.

Unlike traditional polypropylene, our sintered version undergoes a specialized manufacturing process that results in a highly porous and uniform structure. This unique structure provides exceptional mechanical properties, making it ideal for demanding applications where strength and reliability are critical. Additionally, our Sintered Polypropylene offers excellent resistance to corrosion and abrasion, ensuring long-lasting performance in harsh environments.

In addition to its superior physical properties, our Sintered Polypropylene is also environmentally friendly. It is fully recyclable and free from harmful additives, making it a sustainable choice for both manufacturers and end-users. Furthermore, its lightweight nature offers cost savings in transportation and installation, making it a cost-effective solution for various industries.

With our Sintered Polypropylene, you can trust that your products will meet the highest standards for quality and performance. Experience the difference that this advanced material can make in your applications. Trust the expertise and innovation that our Sintered Polypropylene brings to the table.

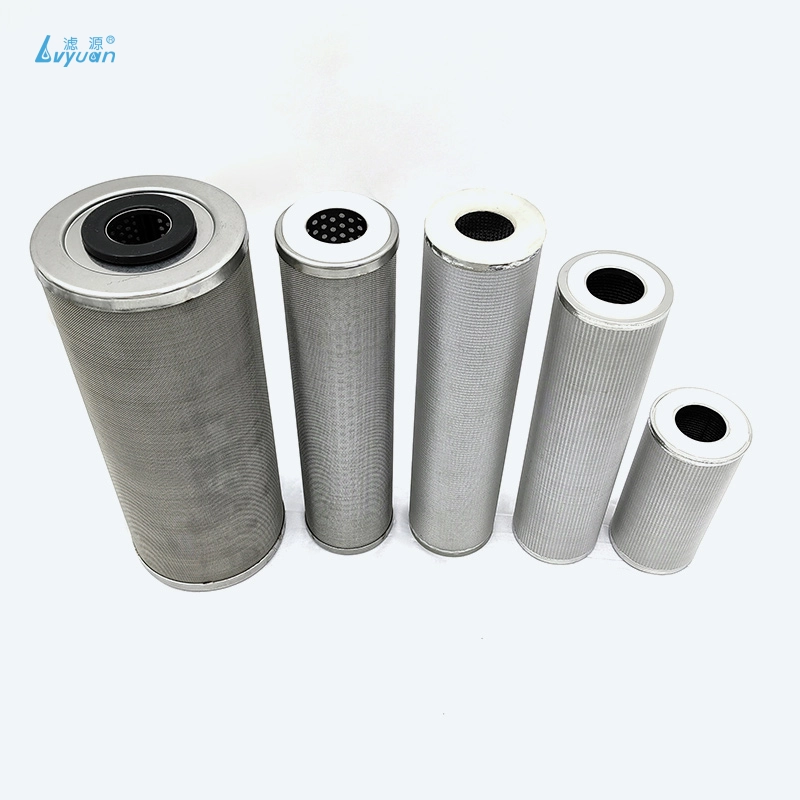

Product Image

Our Advantages

Manufacturing Excellence

Our manufacturing processes adhere to the highest industry standards, ensuring the production of premium-quality stainless steel sintered filters renowned for their durability, efficiency, and longevity.

Sterile Filtration

Sintered metal filters are capable of sterile filtration, crucial in the production of pharmaceutical ingredients and other applications where maintaining a sterile environment is essential.

Vision & Mission

Our vision is to be at the forefront of sintered metal fitter manufacturing, setting new benchmarks for excellence, innovation, and customer satisfaction.Guided by a mission to deliver cutting-edge filtration solutions, we strive to meet and exceed the diverse needs of our global clientele.

Safety and Environmental Protection

The use of sinter metal filters contributes to the reduction of safety risks and environmental impact. Their efficient filtration capabilities help maintain a clean and sterile environment in medical processes, ensuring the safety of patients and the protection of the environment.

Q&A

What materials are commonly used in sintered powder filters?

Common materials include stainless steel (316L, 304L), bronze, Inconel®, Nickel, Monel®, Titanium, and other alloys. The material choice depends on the specific application's requirements.

Can sintered metal filters be customized for specific applications?

Yes, sintered metal filters can be customized based on shape, size, material, filtration accuracy, and other specifications to meet the unique requirements of different applications.

What are the benefits of using sintered plastic porous filters?

Sintered plastic porous filters offer several advantages, including chemical resistance, high temperature resistance, compatibility with a wide range of fluids, uniform pore size distribution, and excellent filtration efficiency.

How often do these stainless steel pleated cartridges need maintenance?

Maintenance frequency depends on the specific application and operating conditions. However, these cartridges are designed for easy installation and maintenance, with cleaning procedures that contribute to their longevity.

If you have any questions or concern, please contact us.

Stainless steel big blue filter housing

Sintered felt filter cartridge

Sintered titanium filter

stainless steel filter water

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions