Find Wholesale Lvyuan Sintered Titanium Filter for Industrial Use

Lvyuan Sintered Titanium Filter: Industrial Strength You Can Rely On

Discover the unmatched utility of the Lvyuan sintered titanium filter, crafted for industrial excellence. Designed to meet the demands of high-performance environments, this filter offers both durability and efficiency. Made from High-Quality sintered titanium, Lvyuan filters are engineered to handle challenging filtration tasks with ease. Whether used in chemical processing, pharmaceutical production, or wastewater treatment, they provide consistent and reliable performance.

Our sintered titanium filters ensure superior strength and corrosion resistance, making them ideal for long-term applications. Their porous structure allows for high permeability, ensuring optimal flow rates while maintaining filtration precision. Easy to install and maintain, Lvyuan filters help reduce operational downtime, saving you time and money.

With a focus on customer satisfaction, Lvyuan is committed to delivering filters that add value to your operations. We understand the importance of quality and reliability, which is why our products undergo rigorous testing to meet international standards. Experience the peace of mind that comes with using a product designed to perform in the toughest conditions.

Invest in a filtrating solution that's as dedicated to excellence as you are. When you find wholesale sintered titanium filter options from Lvyuan, you choose unmatched quality and unwavering support for your industrial needs.

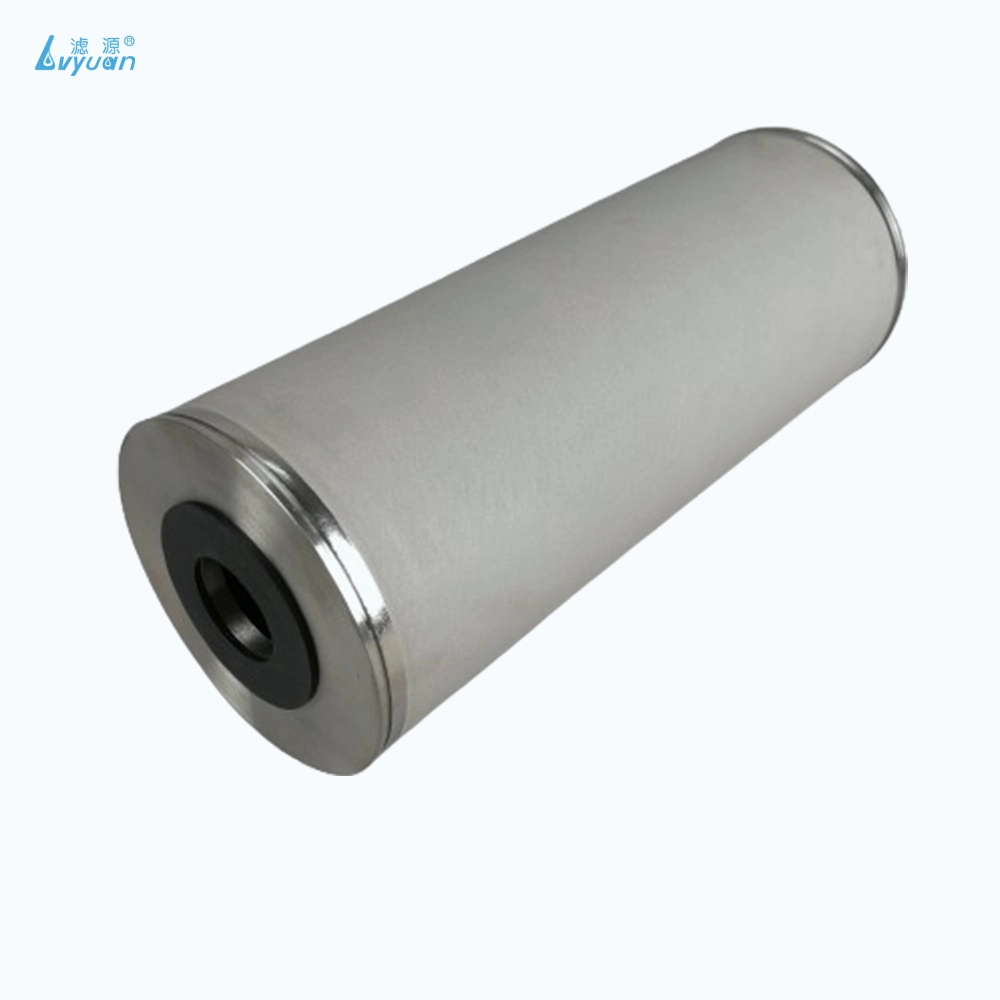

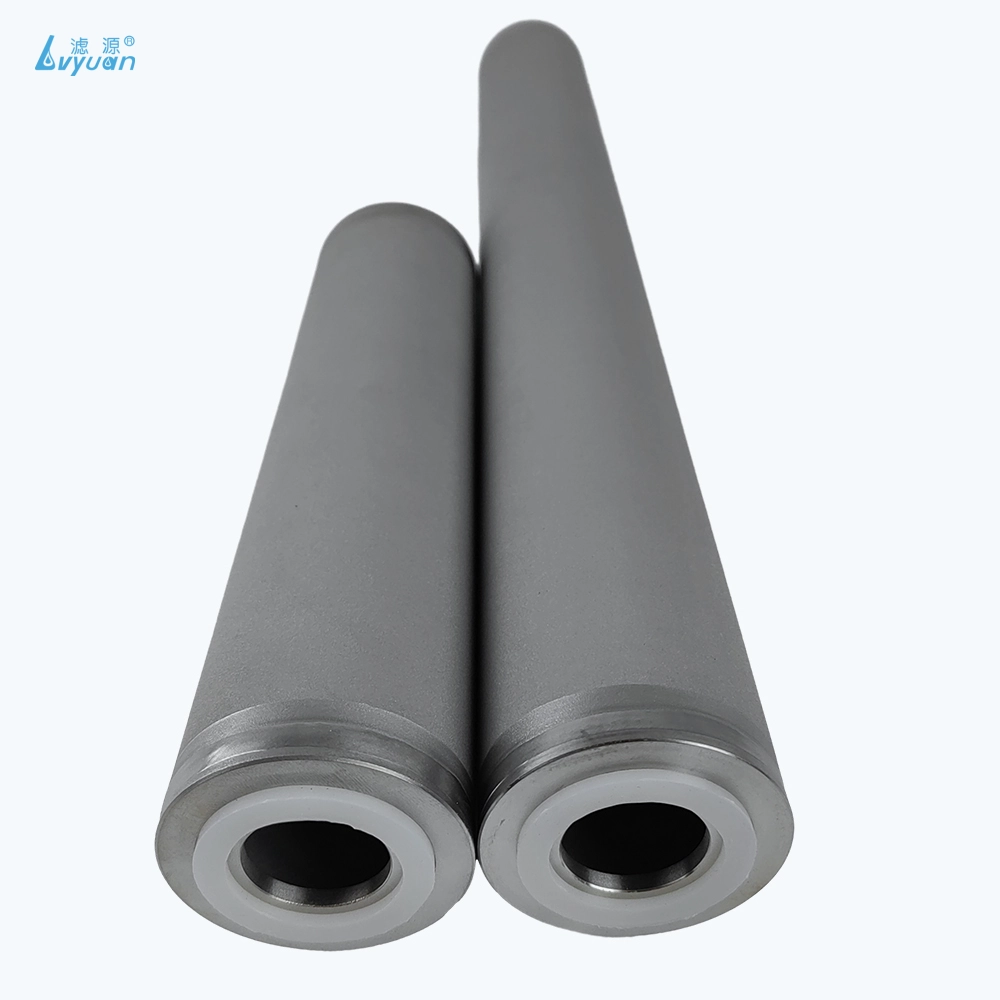

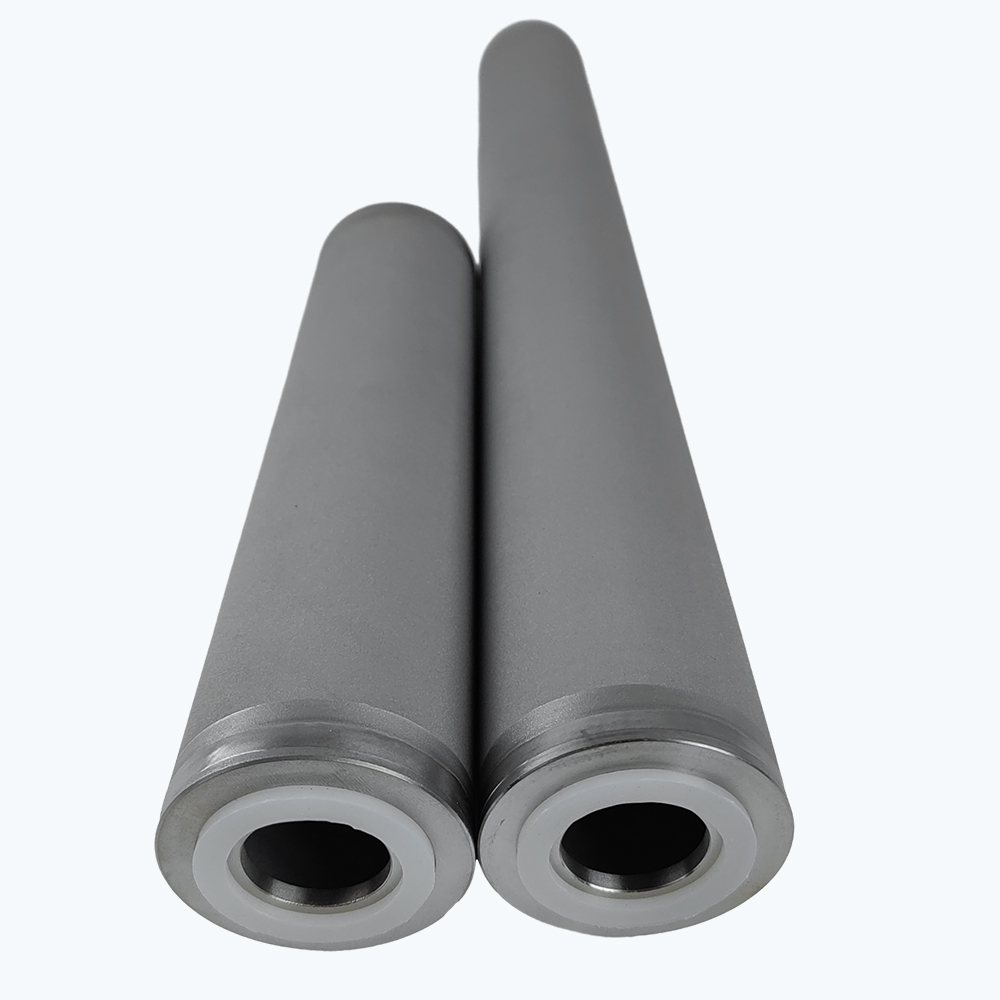

Picture Show

Our Advantages

High-Temperature Resistance

Carbonate hardness optimization. Ions forming scales are removed.

Durable Construction

Crafted from high-quality stainless steel, the pleated filter cartridge boasts exceptional durability.

Consistent Product Quality

By maintaining a high level of cleanliness and removing unwanted particles, sintered metal filters help ensure consistent product quality in terms of taste, texture, and appearance.

High Filtering Precision

Sinter metal filters provide exceptional filtering precision, with pore sizes ranging from 0.1μm to 10μm. This precision allows for the effective removal of contaminants and particles, ensuring the production of pure and high-quality substances in medical applications.

FAQ

How to Calculate Filter Porosity?

Filter porosity is classified into three major types: Primary Porosity, Secondary Porosity, and Effective Porosity. The calculation involves determining the ratio of the volume of gaps in the filter to the total volume, expressed as a percentage.

Porosity = (Volume of Empty Gaps/Total Volume of Filter) x 100

Other methods include:

• Direct Methods: Calculate the entire volume of the porous filter and the volume of a skeletal filter (without pores) to find the porosity.

• Computed Methods: Use modern computer technology to obtain a 3D image of a porous filter and employ defect analysis techniques.

• Water Evaporation Technique: Calculate porosity by determining the difference in weight between the saturated filter in water and the dried filter.

In which industries are industrial sintered metal filter cartridges commonly used?

These cartridges find applications in petrochemicals, pharmaceuticals, water treatment, food processing, automotive, aerospace, and many other industries where precise and reliable filtration is essential.

What is the temperature range that industrial sintered metal filter cartridges can handle?

The temperature range varies based on the material used, but they can typically withstand temperatures from -200°C to 1000°C or even higher for certain alloys.

How are sintered metal filters cleaned?

Cleaning methods for sintered metal filters include backwashing, ultrasonic cleaning, and chemical cleaning. The method depends on the type of contaminants and the filter's specifications.

How do I clean and maintain a sintered mesh filter?

Sintered mesh filters are generally easy to clean. They can be cleaned using methods such as backwashing, ultrasonic cleaning, or chemical cleaning. Regular maintenance helps extend the filter's lifespan and maintain optimal performance.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

stainless steel filter water

Sintered titanium filter

Stainless steel perforated filter

Sintered wire mesh filter

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions