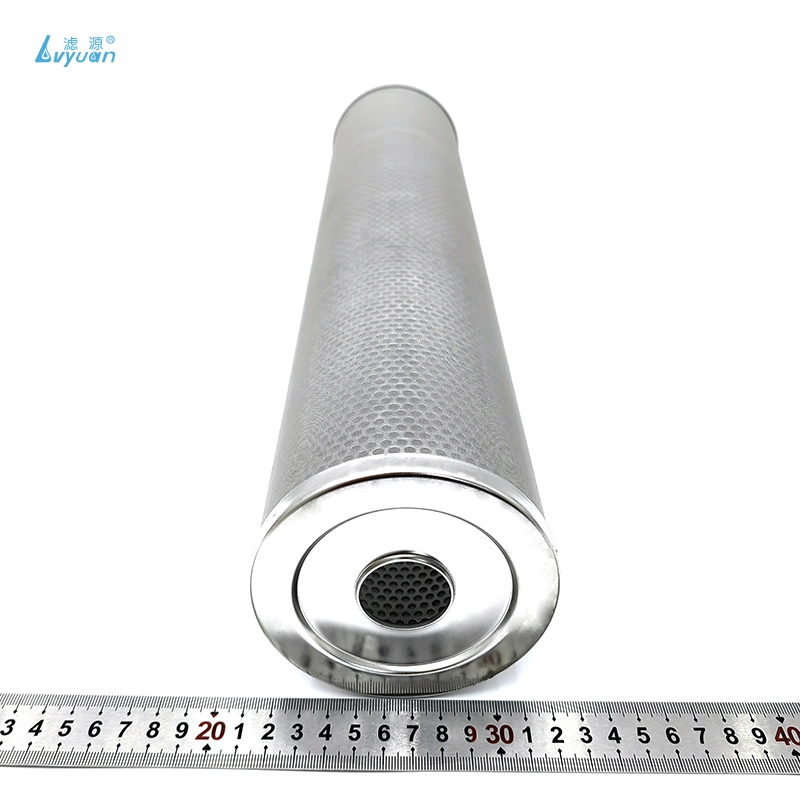

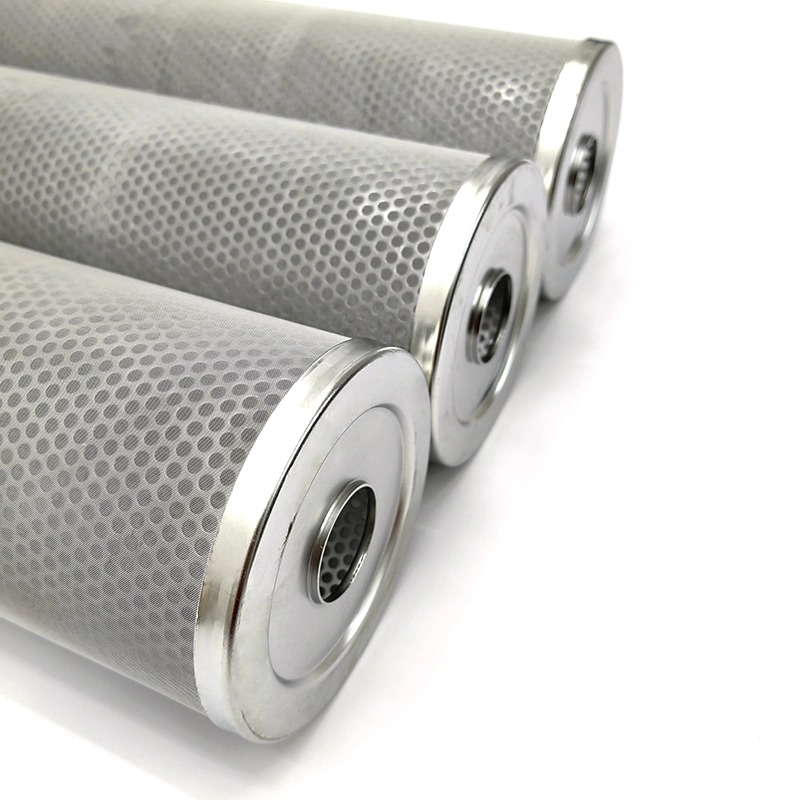

Stainless steel mesh filter

Our stainless steel mesh filters offer dependable filtration accuracy between 1μm and 200μm, delivering precise and efficient filtration for a wide range of applications.

![]() Personalized customization:

Personalized customization:

Whether choosing from these specifications or presenting your unique requirements, Lvyuan ensures a tailored approach to meet your specific needs.

![]() After-Sales Service and Warranty:

After-Sales Service and Warranty:

We offer comprehensive after-sales services, including installation guidance and technical support. Our products also come with a specified warranty period to ensure a worry-free experience for our customers.

Parameters

Material: Stainless Steel (commonly 304, 316, or 316L)

Filtration Accuracy: 1μm to 200μm

Mesh Size: 10 mesh, 100 mesh, etc.

Wire Diameter: typically ranging from 0.025mm to 1mm

Open Area: Percentage of open space in the mesh, affecting flow rate and pressure drop

Weave Type: Plain weave, twill weave, Dutch weave, etc., affecting filtration characteristics

Thickness: Overall thickness of the mesh, often correlating with wire diameter and mesh size

Flow Rate: Capacity for fluid or gas flow through the mesh, influenced by mesh size and open area

Pressure Drop: Difference in pressure before and after the filter, influenced by filtration accuracy and flow rate

Temperature Range: Typically from -100°C to 500°C depending on stainless steel grade

Connectors

• Connectors for our sintered metal tubes offer versatility and compatibility for various applications:

• Standard Interface: Choose from standard interfaces such as 222, 220, or 226 to suit your specific requirements.

• Fast Interface Link: Utilize the fast interface link for quick and efficient connections in your system.

• Thread Connection: Opt for the threaded connection option, providing secure and reliable linking in your setup.

• Flange Connection: Connect seamlessly with flange connections, ensuring stability and ease of installation.

• Rod Connection: Benefit from rod connections for a sturdy and reliable linking method in your application.

• Special Custom Links: Tailor connections to your exact specifications with our special custom links, offering a solution that meets your unique needs.

Application

• Dispersing and Cooling Medium

Ideal for use in high-temperature environments to disperse and cool substances effectively.

• Powder Industry

Uniformly distributes gas and serves as a fluidization plate in the steel industry.

• Gas Distribution

Acts as an ideal porous material for uniform gas distribution and functions as a fluidization plate.

• High-Temperature Furnace Applications

Used in high-temperature furnace applications such as pulverized coal injection, vulcanization, and delivery systems.

• Pharmaceutical Industry

Applied for cleaning, drying, and filtering processes within the pharmaceutical industry.

• Catalyst Support Grid

Functions as a catalyst support grid in various chemical processes.

• Filtration in Various Industries

Serves as a filter in polyester, petroleum, oil, fiber chemical, and water treatment processes.

Key features of stainless steel mesh filters

We’ve got answers.

Browse some answers to our most common questions, or you can drop us a line to ask something else.

Sintered Metal Filter

What is the cleaning process for industrial sintered metal filter cartridges?

Cleaning methods include backwashing, ultrasonic cleaning, chemical cleaning, or a combination of these, depending on the type of contaminants and the cartridge material.

Can industrial sintered metal filter cartridges be customized?

Yes, these cartridges can be customized in terms of dimensions, filtration ratings, materials, and end connections to suit the specific needs of different industrial processes.

How often should industrial-sintered metal filter cartridges be replaced?

The replacement frequency depends on the operating conditions and the level of contaminants in the process. Regular inspection and monitoring help determine the optimal replacement schedule.

How can I select the right industrial sintered filter cartridge for my application?

Consult with the manufacturer or supplier, providing details about your specific requirements, such as filtration needs, operating conditions, and industry standards, to receive guidance on selecting the most suitable cartridge for your application.

In which industries are industrial sintered metal filter cartridges commonly used?

These cartridges find applications in petrochemicals, pharmaceuticals, water treatment, food processing, automotive, aerospace, and many other industries where precise and reliable filtration is essential.

What is the temperature range that industrial sintered metal filter cartridges can handle?

The temperature range varies based on the material used, but they can typically withstand temperatures from -200°C to 1000°C or even higher for certain alloys.

How often should industrial sintered metal filter cartridges be replaced?

The replacement frequency depends on the operating conditions and the level of contaminants in the process. Regular inspection and monitoring help determine the optimal replacement schedule.

Are industrial sintered metal filter cartridges environmentally friendly?

Yes, these cartridges are environmentally friendly due to their reusability and longer lifespan, contributing to reduced waste generation compared to disposable filters.

Want to talk to us

Get in touch

Please fill in the form below. We aim to reply within 1 business day.

Bag filter housing

Bag filter housings are essential components in industrial filtration systems, designed to remove contaminants from liquids. To enhance the functionality and efficiency of bag filter housings, various features can be incorporated.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Stainless steel multi cartridge filter housing

Discover unparalleled filtration efficiency with our Stainless Steel Multi Cartridge Filter Housing – a testament to precision engineering and reliability.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

stainless steel filter water

Lvyuan’s sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Sanitary filter housing

This filter housing will allow you to filter large volumes of nanoemulsion with ease. Sanitary vent and drain valves permit easy venting, draining, sampling, or integrity testing operations. The new cartridge locking design features additional cut-outs for traditional half-moon portions of the Code 7 bayonet locks, enhancing clean ability and drain ability.

Stainless steel pleated filter cartridge

Lvyuan Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions