Custom Sintered SS304 Mesh Filter Cartridge for a U.S. Client

Explore how Lvyuan engineered a Custom Sintered SS304 Mesh Filter Cartridge tailored for a U.S. client, enhancing filtration performance with durability and precision. Leveraging our expertise in stainless steel mesh technology, this bespoke solution ensures optimal flow and filtration efficiency. Discover our commitment to quality and innovation in every custom filter cartridge we produce.

When a U.S.-based industrial filtration company approached us, they were looking for high-performance filter cartridges for a specialized application. The client required 100 pieces of sintered SS304 mesh filter cartridges with specific dimensions and features. Here’s how we met their needs:

Customer Requirements

Material: Sintered SS304 stainless steel mesh for durability and corrosion resistance.

Size: 30-inch length, ensuring compatibility with their existing filtration system.

End Connection: 222 O-ring with a triangular connection, providing secure installation and sealing.

Filtration Accuracy: 10µm to capture fine particles efficiently.

Quantity: 100 pieces for their pilot project.

Our Solution

1. Material Selection:

We chose high-quality SS304 stainless steel, known for its excellent strength, durability, and corrosion resistance. The sintered mesh structure ensures uniform filtration accuracy and long service life.

2. Custom Design:

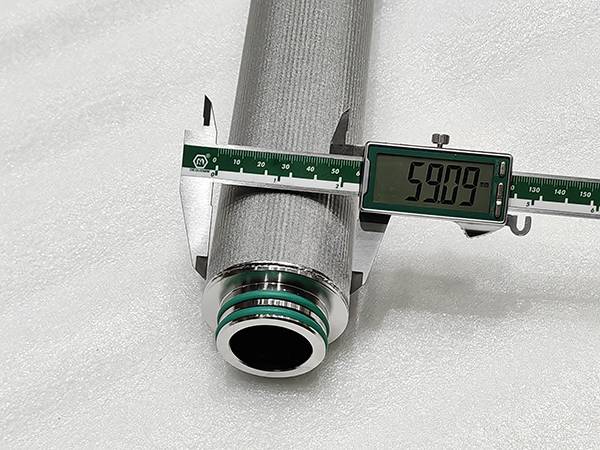

Using precise manufacturing techniques, we tailored the filter cartridges to the client's specifications. The 222 O-ring with a triangular connection was designed for a snug fit, ensuring ease of installation and leak-proof operation.

3.Filtration Accuracy:

The sintered mesh was engineered to provide a reliable 10µm filtration precision, making it suitable for removing fine particles in their application.

4.Testing and Quality Control:

Each cartridge underwent rigorous testing to ensure it met the required standards. From dimensional checks to filtration performance validation, we ensured the products were defect-free.

5.Timely Delivery:

With the order confirmed, our production team worked efficiently to manufacture and deliver all 100 cartridges within the agreed timeline.

Results and Feedback

The customer was highly satisfied with the quality of the filter cartridges. The sintered SS304 mesh performed exceptionally well in their application, meeting both their filtration and durability expectations. Our timely delivery and professional service further solidified our relationship with the client.

Conclusion

This project showcases our ability to deliver customized filtration solutions that meet specific client requirements. Whether it’s the material, size, or filtration accuracy, we are committed to providing products that combine quality, performance, and reliability.

If you’re looking for customized filter cartridges or other filtration solutions, feel free to contact us for expert assistance.

What is Sintered Metal Filter? Complete Guide by Lvyuan

Sintered Filter Element Manufacturing Process and Applications

Applications of Sintered Metal Filters in Manufacturing

Why Lvyuan Is the Best China Manufacturer of Sintered Metal Filters

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Porous Plastic Filter

Are sintered porous filter discs suitable for sterile filtration?

Yes, sintered porous filter discs can be designed for sterile filtration applications, especially when made from materials suitable for high-temperature and chemical sterilization methods.

What types of polymers are used to manufacture sintered plastic porous filters?

Common polymers used in the production of sintered plastic porous filters include polyethylene (PE), polypropylene (PP), polytetrafluoroethylene (PTFE), and polyvinylidene fluoride (PVDF), among others.

For company

What is Lvyuan main products?

Stainless steel filter housing, sintered metals, plastic PE filters, and other filter elements.

Metal mesh filters

Can sintered wire mesh filter be customized?

Yes, sintered wire mesh can be customized in terms of material, pore size, thickness, and dimensions to suit specific filtration requirements. Customization allows for optimal performance in diverse applications.

Sintered Metal Filters

What applications are sintered metal filters suitable for?

Sintered metal filters find applications in petrochemicals, water treatment, food and beverage, pharmaceuticals, automotive, and various industrial processes requiring precise filtration.

Bag filter housing

Bag filter housings are essential components in industrial filtration systems, designed to remove contaminants from liquids. To enhance the functionality and efficiency of bag filter housings, various features can be incorporated.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Stainless steel multi cartridge filter housing

Discover unparalleled filtration efficiency with our Stainless Steel Multi Cartridge Filter Housing – a testament to precision engineering and reliability.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

stainless steel filter water

Lvyuan’s sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Sanitary filter housing

This filter housing will allow you to filter large volumes of nanoemulsion with ease. Sanitary vent and drain valves permit easy venting, draining, sampling, or integrity testing operations. The new cartridge locking design features additional cut-outs for traditional half-moon portions of the Code 7 bayonet locks, enhancing clean ability and drain ability.

Stainless steel pleated filter cartridge

Lvyuan Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions