Sintered Metal Filters | Durable & Efficient Filtration Solutions

Sintered metal filters are a powerful, durable, and efficient solution for a wide range of filtration applications. If you’re looking for a filtration system that offers long-term reliability, minimal maintenance, and high performance, consider Lvyuan’s sintered metal filters.

- Introduction

- What Are Sintered Metal Filters?

- How Sintered Metal Filters Work

- Advantages of Sintered Metal Filters

- Applications of Sintered Metal Filters

- Sintered Metal Filters vs. Other Filtration Technologies

- Choosing the Right Sintered Metal Filter for Your Application

- Why Lvyuan’s Sintered Metal Filters Are the Best Choice

- Conclusion

Introduction

In today’s industrial landscape, efficient filtration is essential for ensuring product quality and operational safety. Whether you work in food and drinks or in petrochemical processes, filtration is very important. It helps keep air and fluids clean. Among the numerous filtration technologies available, sintered metal filters stand out for their strength, durability, and superior filtration efficiency.

Let’s explore why sintered metal filters are the best choice for many industries. Our technology at Lvyuan is leading the way in this area.

What Are Sintered Metal Filters?

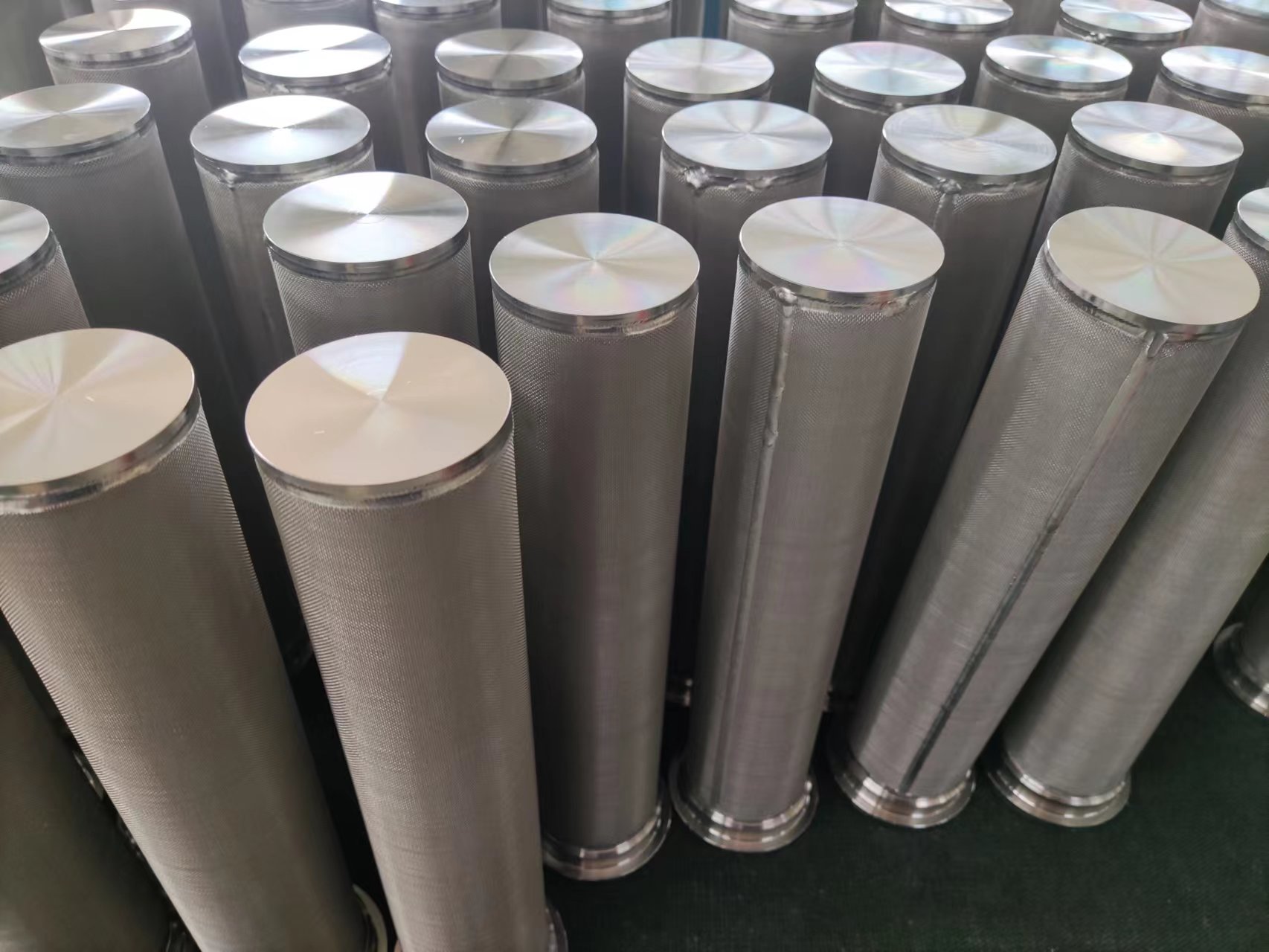

Sintered metal filters are a unique type of filtration technology that utilizes porous metal structures to capture contaminants. Manufacturers typically make these filters from stainless steel, although they can also use other metals like titanium or bronze.

The sintering process bonds metal particles together using heat and pressure. This creates a strong and porous structure. This makes the filters both strong and effective in capturing even the finest particles without compromising flow.

How Sintered Metal Filters Work

Sintered metal filters operate by using multiple filtration mechanisms, such as physical and depth filtration. They consist of multiple layers of porous metal, each with varying pore sizes.

As the fluid or gas moves through the filter, larger particles get stuck in the outer layers. Finer particles are caught in the deeper layers. This design ensures high filtration efficiency with minimal pressure drop, allowing for smooth and continuous operation.

Advantages of Sintered Metal Filters

1. Durability and Longevity

One of the key advantages of sintered metal filters is their exceptional durability. These filters can handle high temperatures, extreme pressures, and harsh environments. This makes them perfect for industries like petrochemicals and pharmaceuticals. Their robust design ensures that they last longer than traditional filters, reducing the need for frequent replacements.

2. High Filtration Efficiency

Sintered metal filters offer superior filtration performance by capturing even the smallest particles while maintaining a consistent flow rate. They are very effective in industries where precision and cleanliness matter. This includes fields like medicine and electronics.

3. Easy Maintenance

Unlike disposable filters, sintered metal filters are reusable and easy to clean. A simple backwashing or ultrasonic cleaning process is often sufficient to restore their full functionality. This reduces downtime and operational costs, contributing to greater overall efficiency.

4. Sustainability

Because sintered metal filters are reusable and have a longer lifespan, they are more environmentally friendly compared to disposable filters. Their ability to withstand multiple cleaning cycles without losing efficiency makes them a sustainable choice for long-term use.

Applications of Sintered Metal Filters

Food and Beverage

In this industry, sintered metal filters are used to filter liquids, gases, and fine particles from the final product. Their ability to maintain sterility while ensuring high filtration efficiency makes them invaluable in these environments.

Petrochemical Industry

These filters are ideal for harsh environments where high-pressure and temperature-resistant filtration systems are needed. Sintered metal filters excel in filtering both liquids and gases under extreme conditions.

Pharmaceutical and Medical

In pharmaceutical manufacturing, clean and sterile environments are critical. Sintered metal filters ensure that production processes meet stringent quality standards by efficiently filtering out contaminants from fluids and gases.

Electronic and Electrical

For sensitive electronic components, clean air and liquid filtration are essential. Sintered metal filters help maintain precision by keeping environments free from harmful particles.

Sintered Metal Filters vs. Other Filtration Technologies

Compared to other filtration systems like mesh or pleated filters, sintered metal filters offer several advantages. They provide superior filtration efficiency, are far more durable, and have a longer service life. While traditional filters may need frequent replacement, sintered filters only require periodic cleaning, making them more cost-effective in the long run.

Choosing the Right Sintered Metal Filter for Your Application

When selecting a sintered metal filter, factors such as pore size, flow rate, and pressure tolerance should be considered. Stainless steel is commonly used for its corrosion resistance, but other metals may be more suitable for specific applications. At Lvyuan, we provide customization options to meet your exact specifications, ensuring you get the best possible filtration solution for your needs.

Why Lvyuan’s Sintered Metal Filters Are the Best Choice

At Lvyuan, we have over a decade of experience in the research and development of sintered metal filters. We are proud to have earned certifications like CE, ROHS, and SGS, guaranteeing the highest levels of quality and safety. With our OEM & ODM services, we offer tailored solutions to meet the unique needs of our clients across various industries. Whether you need standard filters or a customized solution, Lvyuan is here to help.

Conclusion

Sintered metal filters are a powerful, durable, and efficient solution for a wide range of filtration applications. If you’re looking for a filtration system that offers long-term reliability, minimal maintenance, and high performance, consider Lvyuan’s sintered metal filters. Contact us today to learn more about our products and how we can provide the perfect filtration solution for your industry.

What is Sintered Metal Filter? Complete Guide by Lvyuan

Sintered Filter Element Manufacturing Process and Applications

Applications of Sintered Metal Filters in Manufacturing

Why Lvyuan Is the Best China Manufacturer of Sintered Metal Filters

How to Clean Sintered Metal Filters: A Comprehensive Guide

A Comprehensive Guide to Sintered Filters: Features, Production, and Benefits

Porous Plastic Filter

How do I choose the right sintered porous filter disc for my application?

Consider factors such as the nature of the substances being filtered, operating conditions (temperature, pressure), chemical compatibility, and desired filtration precision. Consulting with filtration experts can help guide the selection process.

What is a sintered plastic porous filter?

A sintered plastic porous filter is a filtration device made from polymeric materials that are compressed and heated to form a porous structure with controlled pore sizes and distribution.

How are sintered plastic porous filters manufactured?

Sintered plastic porous filters are manufactured through a process of molding, sintering, and machining. This involves compacting the polymer particles into a desired shape, heating them to a specific temperature to fuse the particles together, and then machining the filter to achieve the desired dimensions and surface finish.

Stainless Steel Cartridge Filter Housing

What are the benefits of using stainless steel cartridge filter housings?

Stainless steel cartridge filter housings offer corrosion resistance, durability, and hygiene, making them suitable for use in a wide range of industries, including food and beverage, pharmaceuticals, chemicals, and water treatment.

Sintered Metal Filter

In which industries are industrial sintered metal filter cartridges commonly used?

These cartridges find applications in petrochemicals, pharmaceuticals, water treatment, food processing, automotive, aerospace, and many other industries where precise and reliable filtration is essential.

What is the temperature range that industrial sintered metal filter cartridges can handle?

The temperature range varies based on the material used, but they can typically withstand temperatures from -200°C to 1000°C or even higher for certain alloys.

Bag filter housing

Bag filter housings are essential components in industrial filtration systems, designed to remove contaminants from liquids. To enhance the functionality and efficiency of bag filter housings, various features can be incorporated.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Stainless steel multi cartridge filter housing

Discover unparalleled filtration efficiency with our Stainless Steel Multi Cartridge Filter Housing – a testament to precision engineering and reliability.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with Lvyuan's sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

stainless steel filter water

Lvyuan’s sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Sanitary filter housing

This filter housing will allow you to filter large volumes of nanoemulsion with ease. Sanitary vent and drain valves permit easy venting, draining, sampling, or integrity testing operations. The new cartridge locking design features additional cut-outs for traditional half-moon portions of the Code 7 bayonet locks, enhancing clean ability and drain ability.

Stainless steel pleated filter cartridge

Lvyuan Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions