Porous Metal Tubes | Advanced Filtration Solutions - Lvyuan

Introduction to Porous Metal Tubes

Explore the superior capabilities of porous metal tubes at Lvyuan, your trusted provider since 2009. These innovative tubes are crafted meticulously for advanced filtration, offering consistent performance across industries like food and beverage, petrochemical, and healthcare. Our products are recognized globally for their high quality and reliability, evident from certifications like CE, ROHS, and SGS.

Why Choose Porous Metal Tubes from Lvyuan?

Porous metal tubes offer unparalleled filtration solutions. Engineered from sintered metal filters, these tubes ensure effective separation, purification, and filtration. They are ideal for challenging environments, where a robust, durable, and efficient product is essential. Lvyuan's porous metal tubes promise precise filtration with long-lasting effectiveness.

Applications Across Diverse Industries

Our porous metal tubes are indispensable in various sectors. In the medical and biopharmaceutical industries, they provide critical solutions for air and liquid filtration. In machinery manufacturing and petrochemicals, these tubes effectively manage filtration needs under demanding conditions. With their wide-ranging applicability, porous metal tubes offer enhanced performance tailored to specific industry requirements.

Lvyuan's Commitment to Quality and Innovation

At Lvyuan, innovation meets reliability. With our R&D expertise, we customize porous metal tubes to meet specific project demands, providing OEM & ODM services. By adhering to rigorous quality standards, we ensure our products exceed industry expectations, making us a preferred choice for over 1,000 customers in 85 countries.

Conclusion: Enhance Your Operations with Lvyuan

Opt for Lvyuan's porous metal tubes to optimize your filtration processes. Trust in our globally recognized, certified products to deliver the performance and reliability your operations demand. Experience the excellence of Lvyuan—where quality, innovation, and customer satisfaction converge.

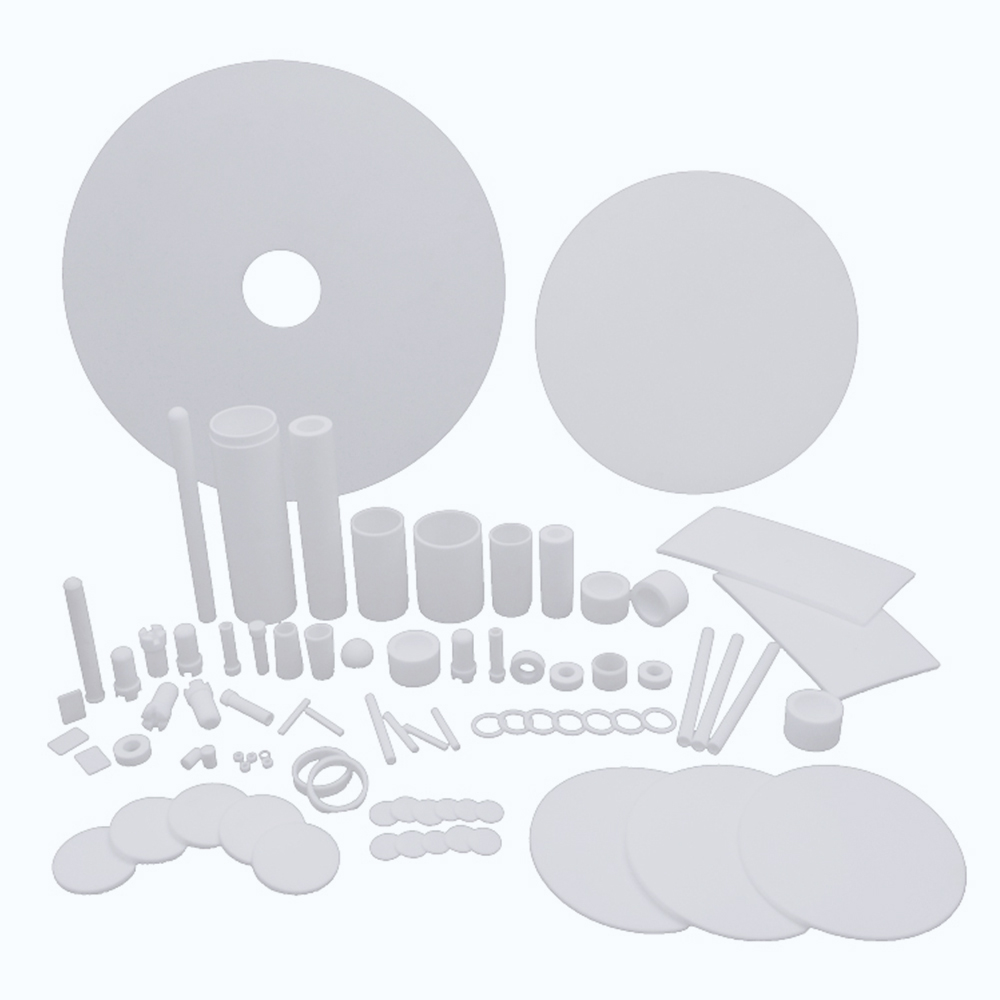

Porous Metal Tubes Display

- Efficient Filtration

The pleated design significantly increases the surface area available for filtration.

- High Filtering Precision

Sinter metal filters provide exceptional filtering precision, with pore sizes ranging from 0.1μm to 10μm. This precision allows for the effective removal of contaminants and particles, ensuring the production of pure and high-quality substances in medical applications.

- Corrosion Resistance

Designed to withstand high temperatures, this filter cartridge maintains structural integrity and filtration efficiency even in applications involving elevated temperatures

- Research & Development

In addition to our commitment to quality, we are also dedicated to environmental responsibility. Our manufacturing processes adhere to sustainable practices, emphasizing efficiency and eco-friendly measures.

- Consistent Product Quality

By maintaining a high level of cleanliness and removing unwanted particles, sintered metal filters help ensure consistent product quality in terms of taste, texture, and appearance.

How do I choose the right sintered metal filter for my application?

To select the appropriate sintered metal filter, consider factors such as the type of fluid or gas, desired flow rate, temperature, pressure, and particle size to be filtered. Our technical team can provide guidance based on your specific requirements.

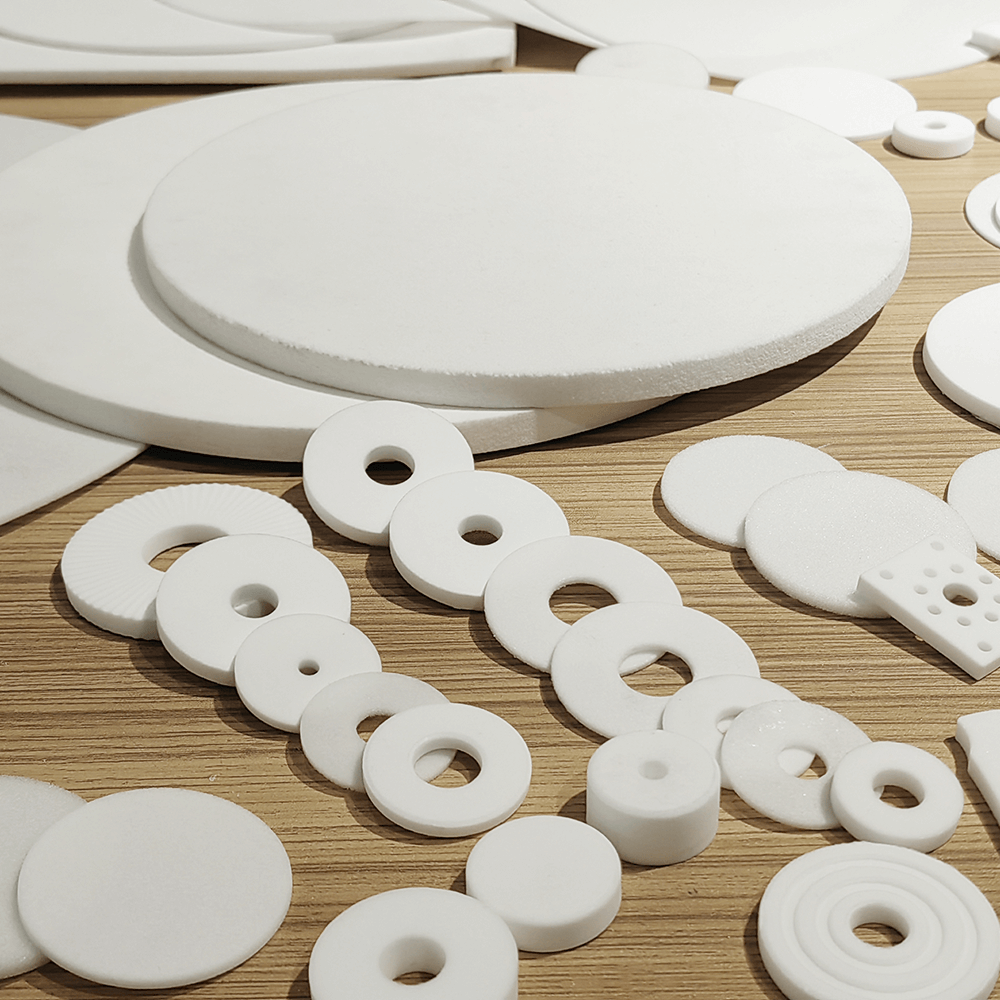

How are sintered plastic porous filters manufactured?

Sintered plastic porous filters are manufactured through a process of molding, sintering, and machining. This involves compacting the polymer particles into a desired shape, heating them to a specific temperature to fuse the particles together, and then machining the filter to achieve the desired dimensions and surface finish.

Do Sintered Titanium Filters Offer High Flow Rates?

Yes, sintered titanium filters support high flow rates at low-pressure drops, optimizing efficiency and ensuring consistent filtration performance.

What materials are commonly used in sintered powder filters?

Common materials include stainless steel (316L, 304L), bronze, Inconel®, Nickel, Monel®, Titanium, and other alloys. The material choice depends on the specific application's requirements.

What are the benefits of using stainless steel cartridge filter housings?

Stainless steel cartridge filter housings offer corrosion resistance, durability, and hygiene, making them suitable for use in a wide range of industries, including food and beverage, pharmaceuticals, chemicals, and water treatment.

What is Sintered Metal Filter? Complete Guide by Lvyuan

Sintered Filter Element Manufacturing Process and Applications

Discover the intricate Sintered Filter Element Manufacturing Process and its diverse applications with Lvyuan. Our expertly crafted filtration solutions ensure high performance and reliability across various industries. Dive into the world of precision-engineered filters designed to optimize your operations.

Applications of Sintered Metal Filters in Manufacturing

Sintered metal filters are vital in various manufacturing processes, offering unmatched efficiency and reliability in separating particles from liquids and gases. Their durability, high-temperature resistance, and versatility make them indispensable in industries ranging from chemical processing to power generation. With the ability to enhance product quality, protect equipment, and meet environmental standards, they play a crucial role in improving operational efficiency and minimizing downtime.

If you're seeking a trusted provider of sintered metal filters for your manufacturing needs, Lvyuan is here to help. With years of experience, cutting-edge technology, and a commitment to quality, Lvyuan offers premium filtration solutions designed to meet the unique requirements of your business. Reach out to Lvyuan today and experience the difference in filtration performance that truly makes a difference in your production line.

Why Lvyuan Is the Best China Manufacturer of Sintered Metal Filters

When it comes to sintered metal filters, Lvyuan stands as the leading manufacturer in China, delivering reliable and high-performance filtration solutions. With years of expertise in industries like petrochemical, power generation, and chemical processing, Lvyuan offers products designed to excel under extreme conditions. Their filters provide efficient particle removal, exceptional durability, and cost-effective maintenance. If you're looking for filters that can withstand high pressures and temperatures, Lvyuan has you covered. Don’t settle for less – reach out to Lvyuan now and let us help you find the perfect filtration solution for your needs!

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions